Silicon carbide (SiC) epitaxy

ʻO ka pā epitaxial, e paʻa ana i ka substrate SiC no ka ulu ʻana i ka ʻāpana epitaxial SiC, waiho ʻia i loko o ke keʻena pane a hoʻopili pololei i ka wafer.

ʻO ka hapa hapalua o ka mahina he mea lawe no nā mea ʻē aʻe o ke keʻena hopena o nā lako epitaxy Sic, ʻoiai ka hapa o ka hapalua mahina e pili ana i ka paipu quartz, e hoʻolauna ana i ke kinoea e hoʻokele i ke kumu susceptor e hoʻololi. hiki ke hoʻopaʻa ʻia i ka wela a hoʻokomo ʻia i loko o ke keʻena pane me ka hoʻopili ʻole ʻana me ka wafer.

ʻO ka epitaxy

ʻO ka pā, e paʻa ana i ka substrate Si no ka ulu ʻana i ka ʻāpana epitaxial Si, waiho ʻia i loko o ke keʻena pane a pili pono i ka wafer.

Aia ke apo preheating ma ke apo o waho o ka pahu substrate Si epitaxial a hoʻohana ʻia no ka calibration a me ka wela. Hoʻokomo ʻia i loko o ke keʻena pane a ʻaʻole pili pono i ka wafer.

He susceptor epitaxial, e paʻa ana i ka substrate Si no ka ulu ʻana i kahi ʻāpana epitaxial Si, waiho ʻia i loko o ke keʻena pane a pili pono i ka wafer.

ʻO ka pahu Epitaxial nā mea nui i hoʻohana ʻia i nā kaʻina hana semiconductor like ʻole, hoʻohana maʻamau i nā lako MOCVD, me ke kūpaʻa wela maikaʻi loa, ke kūpaʻa kemika a me ke kūpaʻa lole, kūpono loa no ka hoʻohana ʻana i nā kaʻina hana wela. Hoʻopili ia i nā wafers.

| Nā waiwai kino o Recrystallized Silicon Carbide | |

| Waiwai | Waiwai maʻamau |

| Mahana hana (°C) | 1600°C (me ka oxygen), 1700°C (hoemi kaiapuni) |

| maʻiʻo SiC | > 99.96% |

| Maikaʻi Si manuahi | <0.1% |

| ʻAno nui | 2.60-2.70 g/cm3 |

| ʻIke ʻia ka porosity | < 16% |

| Ka ikaika hoʻoemi | > 600 MPa |

| Ka ikaika pelu anu | 80-90 MPa (20°C) |

| Ka ikaika piko wela | 90-100 MPa (1400°C) |

| Hoʻonui wela @1500°C | 4.70 10-6/°C |

| ʻO ka wela wela @1200°C | 23 W/m•K |

| Modulus elastic | 240 GPa |

| Ke kū'ē i ka ha'alulu wela | Maikaʻi loa |

| Nā waiwai kino o Sintered Silicon Carbide | |

| Waiwai | Waiwai maʻamau |

| Hoʻohui Kimia | SiC>95%, Si<5% |

| ʻAiʻi Nui | >3.07 g/cm³ |

| ʻIke ʻia ka porosity | <0.1% |

| Modulus o ka rupture ma 20 ℃ | 270 MPa |

| Modulus o ka rupture ma 1200 ℃ | 290 MPa |

| Ka paakiki ma 20 ℃ | 2400 Kg/mm² |

| ʻO ka paʻakikī haʻihaʻi ma 20% | 3.3 MPa · m1/2 |

| ʻO ka Thermal Conductivity ma 1200 ℃ | 45 w/m .K |

| Hoʻonui wela ma 20-1200 ℃ | 4.5 1 ×10 -6/℃ |

| Max.wela hana | 1400 ℃ |

| ʻO ke kūpaʻa haʻalulu wela ma 1200 ℃ | Maikaʻi loa |

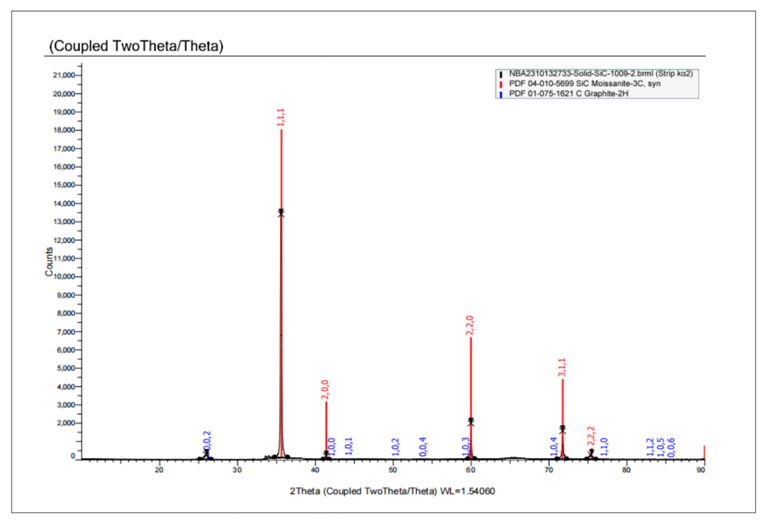

| Nā waiwai kino kumu o nā kiʻiʻoniʻoni CVD SiC | |

| Waiwai | Waiwai maʻamau |

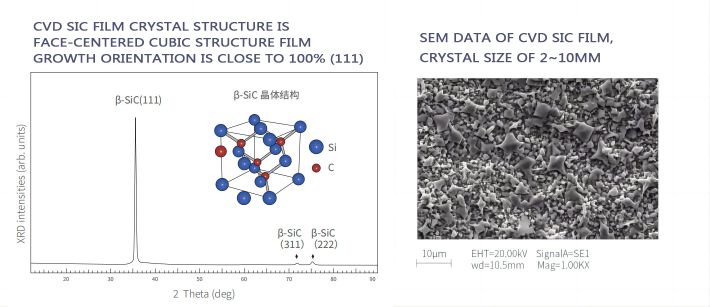

| Hoʻomoe Crystal | FCC β phase polycrystalline, ka mea nui (111). |

| ʻO ka mānoanoa | 3.21 g/cm³ |

| Ka paakiki 2500 | (500g ukana) |

| Ka nui o ka palaoa | 2~10μm |

| Maemae Kemika | 99.99995% |

| Kaha Wela | 640 J·kg-1·K-1 |

| Mahana Sublimation | 2700 ℃ |

| Ikaika Flexural | 415 MPa RT 4-point |

| Opio Modulus | 430 Gpa 4pt piko, 1300 ℃ |

| ʻO ka hoʻoili wela | 300W·m-1·K-1 |

| Hoʻonui wela (CTE) | 4.5×10-6 K -1 |

Nā hiʻohiʻona nui

ʻO ka ʻili he ʻeleʻele a ʻaʻohe pores.

ʻO ka maʻemaʻe kiʻekiʻe, ka nui o ka haumia maʻiʻo <20ppm, maikaʻi ka airtightness.

ʻO ka pale wela kiʻekiʻe, piʻi ka ikaika me ka hoʻonui ʻana i ka mahana hoʻohana, hiki i ka waiwai kiʻekiʻe ma 2750 ℃, sublimation ma 3600 ℃.

Haʻahaʻa elastic modulus, kiʻekiʻe thermal conductivity, haʻahaʻa haʻahaʻa hoʻonui hoʻonui ʻana, a me ka maikaʻi o ke kūʻē ʻana i ka haʻalulu wela.

ʻO ke kūpaʻa kemika maikaʻi, kū i ka waika, alkali, paʻakai, a me nā mea hoʻokalakupua, ʻaʻohe hopena i nā metala hoʻoheheʻe, slag, a me nā mea hoʻoheheʻe ʻē aʻe. ʻAʻole ia e oxidize nui i ka lewa ma lalo o 400 C, a piʻi nui ka oxidation rate ma 800 ℃.

Me ka hoʻokuʻu ʻole ʻana i kekahi kinoea ma nā wela kiʻekiʻe, hiki iā ia ke mālama i kahi ʻūhā o 10-7mmHg ma kahi o 1800°C.

noi huahana

Hoʻoheheʻe ʻia no ka hoʻoheheʻe ʻana i ka ʻoihana semiconductor.

ʻīpuka paipu uila mana kiʻekiʻe.

Palaki e pili ana i ka mea hoʻoponopono voltage.

graphite monochromator no ka X-ray a me ka neutron.

Nā ʻano ʻano like ʻole o nā substrates graphite a me ka uhi ʻana o ka paipu hoʻoheheʻe atomika.

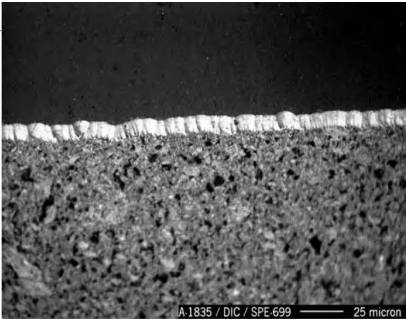

Pyrolytic carbon coating hopena ma lalo o kahi microscope 500X, me ka ʻili paʻa a sila.

ʻO ka uhi ʻana ʻo TaC ka hanauna hou o nā mea wela kiʻekiʻe, me ka ʻoi aku ka maikaʻi o ka wela kiʻekiʻe ma mua o SiC. E like me ka corrosion-kūʻokoʻa uhi, anti-oxidation ka uhi a me ka lole-pale pale, hiki ke hoʻohana 'ia i loko o ke kaiapuni ma luna o 2000C, nui hoʻohana 'ia ma ka aerospace ultra-kiʻekiʻe wela wela wela wela, ke kolu o ka hanauna semiconductor hoʻokahi kristal ulu ulu.

| Nā waiwai kino o ka uhi ʻana o TaC | |

| ʻO ka mānoanoa | 14.3 (g/cm3) |

| Emissivity kiko'ī | 0.3 |

| Koefficient hoʻonui wela | 6.3 10/K |

| Paʻakiki (HK) | 2000 HK |

| Kūʻē | 1x10-5 Ohm*cm |

| Paʻa wela | <2500 ℃ |

| Hoʻololi ka nui o ka graphite | -10~-20um |

| Mānoanoa uhi | ≥220um waiwai maʻamau (35um±10um) |

ʻIke ʻia nā ʻāpana paʻa CVD SILICON CARBIDE ma ke ʻano he koho mua no nā apo RTP/EPI a me nā kumu a me nā ʻāpana etch cavity plasma e hana ana ma nā ʻōnaehana kiʻekiʻe e koi ʻia ana nā mahana hana (> 1500 ° C), ʻoi aku ka kiʻekiʻe o nā koi no ka maʻemaʻe (> 99.9995%). a ʻoi aku ka maikaʻi o ka hana inā kiʻekiʻe ke kiʻekiʻe o nā kemika tol. ʻAʻole i loaʻa i kēia mau mea nā ʻāpana lua ma ka ʻaoʻao o ka palaoa, no laila e liʻiliʻi nā ʻāpana i nā ʻāpana ma mua o nā mea ʻē aʻe. Eia hou, hiki ke hoʻomaʻemaʻe ʻia kēia mau ʻāpana me ka HF/HCI wela me ka liʻiliʻi o ka hoʻohaʻahaʻa ʻana, e hopena i nā mea liʻiliʻi a me ke ola o ka lawelawe ʻana.