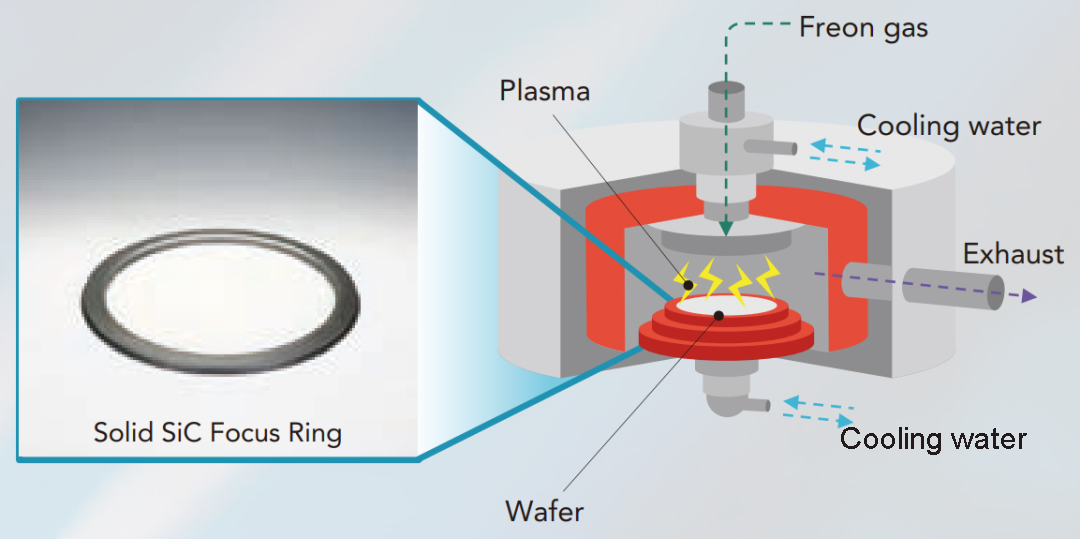

I nā mea hana etching plasma, he mea koʻikoʻi nā ʻāpana seramika, me kaapo maka.ʻO ka apo maka, kau ʻia a puni ka wafer a pili pono me ia, he mea nui ia no ka hoʻokuʻu ʻana i ka plasma ma luna o ka wafer ma ke kau ʻana i ka volta i ke apo. Hoʻonui kēia i ka kūlike o ke kaʻina hana etching.

Hoʻohana ʻia ʻo SiC Focus Rings i nā Mīkini Etching

Nā ʻāpana SiC CVDi nā mīkini etching, e like meapo apo, hau hau, platens, a me nā apo lihi, ua makemake ʻia ma muli o ka haʻahaʻa haʻahaʻa o SiC me ka chlorine a me ka fluorine-based etching gases a me kāna conductivity, e lilo ia i mea kūpono no nā lako etching plasma.

ʻO nā pono o ka SiC ma ke ʻano he Ring Ring Material

Ma muli o ka hōʻike pololei ʻana i ka plasma i loko o ke keʻena hoʻonaninani vacuum, pono e hana ʻia nā apo kiko mai nā mea pale plasma. ʻO nā apo kuʻuna kuʻuna, i hana ʻia mai ke silicon a i ʻole ka quartz, e hōʻeha ʻia i ke kūpaʻa etching maikaʻi ʻole i nā plasma e pili ana i ka fluorine, e alakaʻi ana i ka corrosion wikiwiki a hoʻemi i ka pono.

Hoʻohālikelike ma waena o Si a me CVD SiC Focus Rings:

1. Kiʻekiʻe kiʻekiʻe:Hoemi i ka leo etching.

2. ʻAha Bandgap: Hāʻawi i ka hoʻokaʻawale maikaʻi loa.

3. Kiʻekiʻe Thermal Conductivity & Haʻahaʻa Expansion Coefficient: Kūleʻa i ka haʻalulu wela.

4. Elasticity kiʻekiʻe:Kūleʻa maikaʻi i ka hopena mechanical.

5. 'Oolea ki'eki'e: ʻAʻahu a pale i ka corrosion.

Kaʻana like ʻo SiC i ka conductivity uila o ke silika ʻoiai e hāʻawi ana i ke kūpaʻa kiʻekiʻe i ka etching ionic. Ke holomua nei ka miniaturization circuit circuit, piʻi ka koi no nā kaʻina hana etching ʻoi aku ka maikaʻi. ʻO nā mea hana etching plasma, ʻoi aku ka poʻe e hoʻohana ana i ka capacitive coupled plasma (CCP), pono i ka ikehu plasma kiʻekiʻe, e hana anaNā apo kikoʻī SiCmahuahua kaulana.

ʻO Si a me CVD SiC Focus Ring Parameters:

| ʻĀpana | Silika (Si) | CVD Silicon Carbide (SiC) |

| Māmā (g/cm³) | 2.33 | 3.21 |

| ʻAha Band (eV) | 1.12 | 2.3 |

| ʻO ka hoʻoili wela (W/cm°C) | 1.5 | 5 |

| Koefficient Hoonui wela (x10⁻⁶/°C) | 2.6 | 4 |

| Modulus Elastic (GPa) | 150 | 440 |

| ʻoʻoleʻa | lalo | Kiʻekiʻe |

Ke Kaʻina Hana ʻana o nā Rings Focus SiC

I nā lako semiconductor, hoʻohana mau ʻia ka CVD (Chemical Vapor Deposition) e hana i nā ʻāpana SiC. Hana ʻia nā apo kiko ma ka waiho ʻana iā SiC i loko o nā ʻano kikoʻī ma o ka waiho ʻana o ka mahu, a ukali ʻia e ka hana mīkini e hana i ka huahana hope. Hoʻopaʻa ʻia ka lākiō mea no ka waiho ʻana i ka mahu ma hope o ka hoʻokolohua nui ʻana, e hoʻohālikelike ʻia nā ʻāpana e like me ka resistivity. Eia nō naʻe, pono nā mea hana etching ʻokoʻa i nā apo kikoʻī me nā resistivity like ʻole, pono i nā hoʻokolohua lākiō mea hou no kēlā me kēia kikoʻī, ʻo ia ka manawa a me ke kumu kūʻai.

Ma ke koho ʻanaNā apo kikoʻī SiCmaiSemicera Semiconductor, hiki i nā mea kūʻai ke hoʻokō i nā pono o nā pōʻai pani lōʻihi a me ka hana kiʻekiʻe me ka ʻole o ka piʻi nui ʻana o ke kumukūʻai.

Nā ʻāpana hoʻoponopono wela wela (RTP).

ʻO nā waiwai wela kūikawā o CVD SiC he mea kūpono ia no nā noi RTP. ʻO nā ʻāpana RTP, me nā apo lihi a me nā platens, pōmaikaʻi mai CVD SiC. I ka wā o ka RTP, hoʻohana ʻia nā puʻupuʻu wela nui i nā wafers pākahi no nā manawa pōkole, a ukali ʻia e ka hoʻomaha wikiwiki. ʻO nā apo ʻaoʻao CVD SiC, ʻeleʻele a me ka haʻahaʻa haʻahaʻa wela, ʻaʻole mālama i ka wela nui, ʻaʻole i hoʻopilikia ʻia e nā kaʻina hana hoʻomehana a me ka hoʻoluʻu.

Nā mea hoʻoheheʻe plasma

ʻO ke kūpaʻa kemika kiʻekiʻe o CVD SiC e kūpono ia no nā noi etching. Nui nā keʻena etching e hoʻohana ana i nā papa hāʻawi kinoea CVD SiC e puʻunaue i nā kinoea etching, i loaʻa nā tausani o nā puka liʻiliʻi no ka hoʻopuehu plasma. Hoʻohālikelike ʻia i nā mea ʻē aʻe, he haʻahaʻa haʻahaʻa ka CVD SiC me nā chlorine a me nā kinoea fluorine. I ka etching maloʻo, hoʻohana mau ʻia nā ʻāpana CVD SiC e like me nā apo kiko, nā platens ICP, nā apo palena, a me nā poʻo ʻauʻau.

ʻO nā apo kiko SiC, me kā lākou voltage i noi ʻia no ka nānā ʻana i ka plasma, pono e lawa ka conductivity. Hana ʻia me ka silikoni, ʻike ʻia nā apo kikoʻī i nā kinoea reactive i loaʻa ka fluorine a me ka chlorine, e alakaʻi ana i ka ʻino ʻole. ʻO nā apo kikoʻī SiC, me kā lākou pale ʻana i ka corrosion, hāʻawi i nā ola lōʻihi i hoʻohālikelike ʻia me nā apo silika.

Ka Hoʻohālikelike Ola:

· Nā Rings Kūlana SiC:Hoʻololi i kēlā me kēia 15 a 20 mau lā.

· Nā apo hoʻopaʻa manaʻo Silicon:Hoʻololi ʻia i kēlā me kēia 10 a 12 mau lā.

ʻOiai ʻo nā apo SiC he 2 a 3 mau manawa ʻoi aku ka maikaʻi ma mua o nā apo silika, ʻo ka pōʻai hoʻololi hoʻolōʻihi e hōʻemi ana i nā kumukūʻai hoʻololi ʻāpana holoʻokoʻa, no ka mea, ua hoʻololi ʻia nā ʻāpana lole a pau o ke keʻena i ka manawa e wehe ʻia ai ke keʻena no ke pani apo apo.

ʻO Semicera Semiconductor's SiC Focus Rings

Hāʻawi ʻo Semicera Semiconductor i nā apo kiko SiC i nā kumukūʻai kokoke i nā apo silika, me kahi manawa alakaʻi ma kahi o 30 mau lā. Ma ka hoʻohui ʻana i nā apo kikoʻī o Semicera's SiC i nā lako etching plasma, hoʻomaikaʻi maikaʻi ʻia ka maikaʻi a me ka lōʻihi, e hōʻemi ana i nā kumukūʻai mālama holoʻokoʻa a me ka hoʻonui ʻana i ka pono hana. Eia hou, hiki iā Semicera ke hana i ka resistivity o nā apo apo e hoʻokō i nā koi o ka mea kūʻai aku.

Ma ke koho ʻana i nā apo kiʻekiʻe SiC mai Semicera Semiconductor, hiki i nā mea kūʻai ke hoʻokō i nā pono o nā kaʻina hoʻololi lōʻihi a me ka hana maikaʻi ʻole me ka piʻi nui ʻole o ke kumukūʻai.

Ka manawa hoʻouna: Jul-10-2024