I kēia manawa, ʻo ke kolu o ka hanauna o nā semiconductor i hoʻomalu ʻia ekalapona kalapona. I ke kumu kūʻai o kāna mau mea hana, ʻo ka substrate he 47%, a ʻo ka epitaxy he 23%. ʻO nā mea ʻelua i hui pū ʻia ma kahi o 70%, ʻo ia ka hapa nui o kakalapona kalaponakaulahao ʻoihana hana ʻenehana.

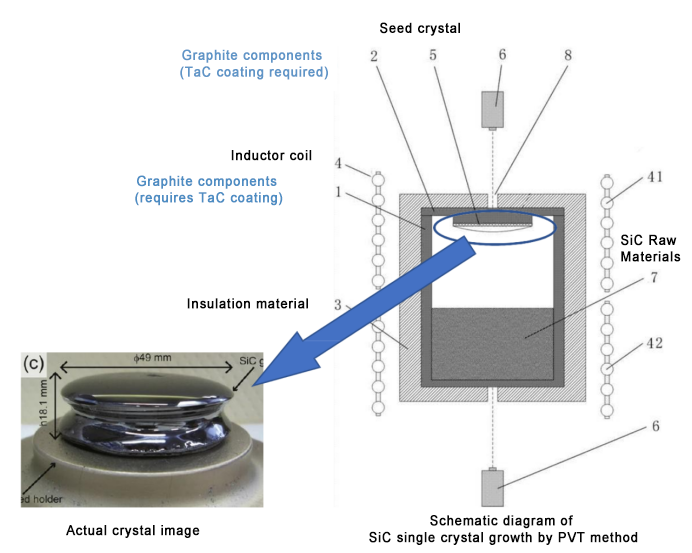

ʻO ke ʻano hana maʻamau no ka hoʻomākaukau ʻanakalapona kalaponaʻO nā kristal hoʻokahi ke ala PVT (physical vapor transport). ʻO ke kumumanaʻo ka hana ʻana i nā mea maka i loko o kahi ʻāpana wela kiʻekiʻe a me ke aniani hua ma kahi haʻahaʻa haʻahaʻa haʻahaʻa. ʻO nā mea maka i kahi mahana kiʻekiʻe e decompose a hoʻopuka pololei i nā mea kinoea me ka ʻole o ka wai. Lawe ʻia kēia mau mea kinoea i loko o ke aniani hua ma lalo o ka hoʻokele ʻana o ka gradient mahana axial, a nucleate a ulu ma ka ʻanoʻano kristal e hana i kahi aniani carbide hoʻokahi. I kēia manawa, hoʻohana nā hui haole e like me Cree, II-VI, SiCrystal, Dow a me nā hui kūloko e like me Tianyue Advanced, Tianke Heda, a me Century Golden Core i kēia ʻano.

ʻOi aku ma mua o 200 mau ʻano aniani o ka silicon carbide, a koi ʻia ka mana pololei loa e hoʻohua i ke ʻano kristal hoʻokahi i makemake ʻia (ʻo ke ʻano nui he 4H crystal form). Wahi a Tianyue Advanced's prospectus, ka hui o ke kookoo aniani o ka hui ma 2018-2020 a me H1 2021 he 41%, 38.57%, 50.73% a me 49.90% pakahi, a me ka substrate hua mai he 72.61%, 75.15%, a me 75.15%. ʻO 37.7% wale nō ka hopena o kēia manawa. ʻO ka lawe ʻana i ke ʻano PVT koʻikoʻi ma ke ʻano he laʻana, ʻo ka haʻahaʻa haʻahaʻa ma muli o nā pilikia aʻe i ka hoʻomākaukau ʻana i ka substrate SiC:

1. Paʻakikī i ka mālama ʻana i ka mahina ʻai: Pono e hana ʻia nā koʻokoʻo kristal SiC ma kahi kiʻekiʻe o 2500 ℃, ʻoiai ʻo 1500 ℃ wale nō nā silicon crystals, no laila e koi ʻia nā kapuahi aniani kūikawā kūikawā, a pono e mālama pono ʻia ka ulu ulu ʻana i ka wā hana. , ka mea paʻakikī loa e hoʻomalu.

2. ʻO ka wikiwiki o ka hana ʻana: ʻO ka ulu ʻana o nā mea silika maʻamau ʻo 300 mm i kēlā me kēia hola, akā hiki i ka silicon carbide hoʻokahi kristal ke ulu i 400 microns i kēlā me kēia hola, ʻo ia ka mea kokoke i 800 mau manawa o ka ʻokoʻa.

3. ʻO nā koi kiʻekiʻe no nā ʻāpana huahana maikaʻi, a paʻakikī ka hoʻokele ʻana o ka pahu ʻeleʻele i ka manawa: ʻO nā ʻāpana kumu o nā wafers SiC me ka microtube density, dislocation density, resistivity, warpage, surface roughness, etc. pono e hoʻomalu pono i nā ʻāpana e like me ka lākiō silicon-carbon, ka ulu ʻana o ka mahana gradient, ka nui o ka ulu ʻana o ka kristal, a me ke kaomi ea. Inā ʻaʻole, hiki ke hoʻokomo ʻia nā polymorphic, e hopena i nā kristal kūpono ʻole. I loko o ka pahu ʻeleʻele o ka graphite crucible, ʻaʻole hiki ke nānā i ke kūlana o ka ulu ʻana o ke aniani i ka manawa maoli, a pono ka hoʻomalu ʻana i ka wela wela, ka hoʻohālikelike ʻana i nā mea, a me ka ʻike ʻike.

4. Paʻakikī i ka hoʻonui ʻana i ke aniani: Ma lalo o ke ʻano o ka lawe ʻana i ke kinoea, paʻakikī loa ka ʻenehana hoʻonui o ka ulu ʻana o ka kristal SiC. Ke piʻi aʻe ka nui aniani, piʻi nui ka paʻakikī o ka ulu ʻana.

5. ʻO ka maʻamau haʻahaʻa: ʻO ka haʻahaʻa haʻahaʻa ka nui o nā loulou ʻelua: (1) ʻO ke koʻokoʻo koʻokoʻo hua = semiconductor-grade crystal rod output/(semiconductor-grade crystal rod output + non-semiconductor-grade crystal rod output) × 100%; (2) Hoʻohua substrate = puka pani kūpono kūpono/(hua hoʻopuka substrate kūpono + puka puka substrate kūpono ʻole) × 100%.

I ka hoʻomākaukauʻana i ke kūlana kiʻekiʻe a me ka hua kiʻekiʻenā mea hoʻoheheʻe kalapona silika, Pono ke kumu i nā mea ʻoi aku ka maikaʻi o ke kahua wela e hoʻomalu pono i ka mahana hana. ʻO nā pahu hoʻoheheʻe wela i hoʻohana ʻia i kēia manawa ʻo ia nā ʻāpana graphite maʻemaʻe kiʻekiʻe, i hoʻohana ʻia e wela a hoʻoheheʻe i ka pauka kalapona a me ka pauka silika a mālama i ka mahana. Loaʻa i nā mea graphite nā hiʻohiʻona o ka ikaika kikoʻī kiʻekiʻe a me ka modulus kikoʻī, ke kūpaʻa haʻalulu maikaʻi a me ka pale ʻana i ka corrosion, akā loaʻa iā lākou nā hemahema o ka maʻalahi o ka oxidized i nā wahi oxygen kiʻekiʻe, ʻaʻole kūpaʻa i ka ammonia, a me ke kūpaʻa maikaʻi ʻole. I ke kaʻina hana o ka silika carbide hoʻokahi kristal ulu awafer epitaxial silicon carbidehana, he paʻakikī ke hoʻokō i nā koi koi ikaika o ka poʻe no ka hoʻohana ʻana i nā mea graphite, kahi e hoʻopaʻa pono ai i kona hoʻomohala ʻana a me ka hoʻohana pono ʻana. No laila, ua hoʻomaka ka puka ʻana o nā uhi wela wela e like me tantalum carbide.

2. Na ano oʻO Tantalum Carbide Coating

He wahi hehee ko TaC ceramic a hiki i 3880 ℃, paʻakikī kiʻekiʻe (Mohs hardness 9-10), conductivity thermal nui (22W·m-1·K−1), ikaika kulou nui (340-400MPa), a me ka hoʻonui wela liʻiliʻi. coefficient (6.6×10−6K−1), a hōʻike i ke kūpaʻa thermochemical maikaʻi loa a me nā waiwai kino maikaʻi loa. Loaʻa iā ia ka hoʻohālikelike kemika maikaʻi a me ka hoʻopili mechanical me ka graphite a me nā mea hoʻohui C/C. No laila, hoʻohana nui ʻia ka uhi TaC i ka pale wela aerospace, ka ulu ʻana o ka kristal hoʻokahi, ka uila uila, a me nā mea lapaʻau.

i uhi ʻia ʻo TaCʻOi aku ka maikaʻi o ka graphite ma mua o ka graphite ʻole a i ʻole ka graphite i uhi ʻia ʻo SiC, hiki ke hoʻohana paʻa ʻia i nā mahana kiʻekiʻe o 2600 °, ʻaʻole e pane me nā mea metala he nui. ʻO ia ka uhi maikaʻi loa i ke kolu o nā hanauna semiconductor hoʻokahi ulu kristal a me nā hiʻohiʻona wafer etching. Hiki iā ia ke hoʻomaikaʻi nui i ka mana o ka mahana a me nā haumia i ke kaʻina hana a hoʻomākaukaukiʻekiʻe kiʻekiʻe silicon carbide wafersa piliepitaxial wafers. He kūpono loa ia no ka ulu ʻana i nā kristal hoʻokahi GaN a i ʻole AlN me nā lako MOCVD a me ka ulu ʻana i nā kristal hoʻokahi SiC me nā lako PVT, a ua hoʻomaikaʻi nui ʻia ka maikaʻi o nā kristal hoʻokahi ulu.

III. ʻO nā pono o ka Tantalum Carbide Coated Devices

Hiki i ka hoʻohana ʻana o Tantalum Carbide TaC coating ke hoʻopau i ka pilikia o nā hemahema ʻaoʻao a hoʻomaikaʻi i ka maikaʻi o ka ulu ʻana o ka kristal. ʻO ia kekahi o nā kuhikuhi ʻenehana nui o ka "ulu wikiwiki, ulu mānoanoa, a ulu lōʻihi". Ua hōʻike pū ʻia ka noiʻi ʻoihana e hiki i ka Tantalum Carbide Coated Graphite Crucible ke hoʻokō i ka hoʻomehana like ʻole, a laila e hāʻawi ana i ka mana kaʻina hana maikaʻi loa no ka ulu ʻana o ka kristal SiC hoʻokahi, no laila e hōʻemi nui ai i ka hiki ke hoʻokumu ʻia ka polycrystalline ma ka lihi o nā kristal SiC. Eia kekahi, ʻelua mau pono nui ʻo Tantalum Carbide Graphite Coating:

(I) Hoemi i na hemahema SiC

Ma ke ʻano o ka hoʻomalu ʻana i nā hemahema ʻeleʻele hoʻokahi SiC, ʻekolu mau ala koʻikoʻi. Ma waho aʻe o ka hoʻonui ʻana i nā ʻāpana ulu a me nā kumu kumu kiʻekiʻe (e like me ka SiC source powder), me ka hoʻohana ʻana i ka Tantalum Carbide Coated Graphite Crucible hiki ke hoʻokō i ka maikaʻi kristal maikaʻi.

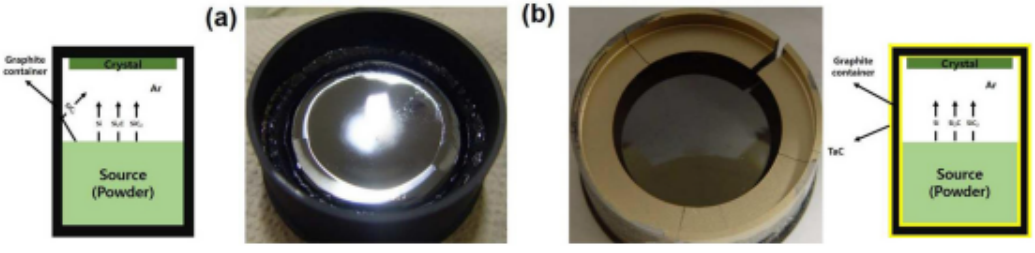

Kiʻi kiʻi kiʻi o ka pahu graphite maʻamau (a) a me ke kīʻaha TAC i uhi ʻia (b)

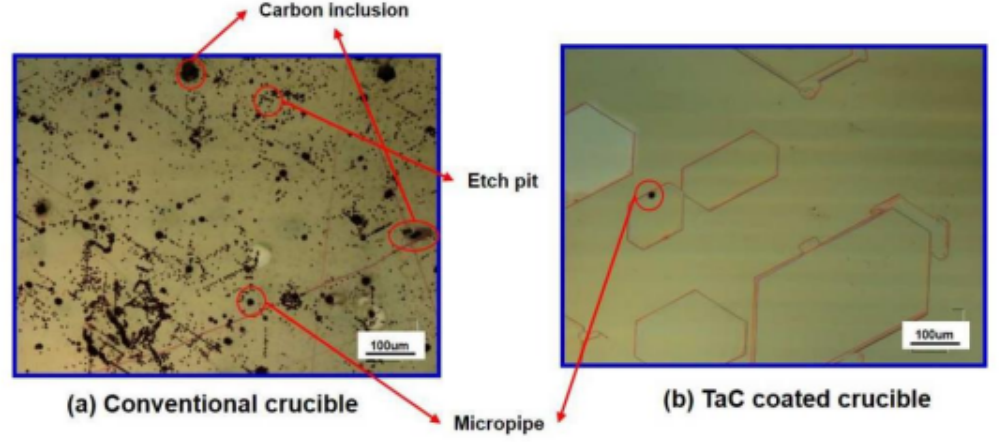

Wahi a ka noiʻi a ke Kulanui o ʻEulopa Hikina ma Korea, ʻo ka haumia nui i ka ulu ʻana o ka kristal SiC he nitrogen, a ʻo ka tantalum carbide coated graphite crucibles hiki ke hoʻopaʻa pono i ka hoʻohui ʻana o nā kristal SiC, a laila e hōʻemi i ka hanauna o nā hemahema e like me nā micropipes a me ka hoʻomaikaʻi ʻana i ke aniani. maikaʻi. Ua hōʻike nā haʻawina ma lalo o nā kūlana like, ʻo ka nui o ka lawe ʻana o nā wafers SiC i ulu i loko o nā crucibles graphite maʻamau a me nā crucibles uhi ʻia ʻo TAC ma kahi o 4.5 × 1017/cm a me 7.6 × 1015/cm, kēlā me kēia.

Ka hoʻohālikelike ʻana o nā hemahema i loko o nā kristal hoʻokahi SiC i ulu i loko o nā crucibles graphite maʻamau (a) a me nā crucibles uhi ʻia ʻo TAC (b)

(II) Hoʻomaikaʻi i ke ola o nā crucibles graphite

I kēia manawa, ʻoi aku ka kiʻekiʻe o ke kumukūʻai o nā kristal SiC, a ʻo ke kumukūʻai o nā mea hoʻohana graphite e pili ana i 30%. ʻO ke kī i ka hōʻemi ʻana i ke kumukūʻai o nā mea hoʻohana graphite e hoʻonui i kona ola lawelawe. Wahi a ka ʻikepili mai kahi hui noiʻi Pelekane, hiki i ka tantalum carbide coatings ke hoʻonui i ke ola lawelawe o nā mea graphite e 30-50%. Wahi a kēia helu ʻana, ʻo ka hoʻololi wale ʻana i ka tantalum carbide coated graphite hiki ke hōʻemi i ke kumukūʻai o nā kristal SiC e 9% -15%.

4. Tantalum carbide uhi kaʻina hana hoʻomākaukau

Hiki ke hoʻokaʻawale ʻia ke ʻano o ka hoʻomākaukau ʻana i ka uhi ʻana o TaC i ʻekolu mau ʻāpana: ke ʻano hana paʻa, ke ʻano hana wai a me ke ʻano o ke kaʻina. ʻO ke ala paʻa paʻa ka nui o ke ʻano hoʻemi a me ke ʻano kemika; ʻO ke ʻano o ke ʻano wai e pili ana i ke ʻano paʻakai hoʻoheheʻe ʻia, ke ʻano sol-gel (Sol-Gel), ke ʻano slurry-sintering, ke ʻano hoʻoheheʻe plasma; ʻO ke kaʻina hana kinoea e pili ana i ka hoʻoheheʻe ʻana i ka mahu (CVD), ka infiltration mahu (CVI) a me ka deposition mahu kino (PVD). Loaʻa i nā ʻano hana like ʻole ko lākou pono a me nā hemahema. Ma waena o lākou, ʻo CVD kahi ʻano oʻo a hoʻohana nui ʻia no ka hoʻomākaukau ʻana i nā uhi TaC. Me ka hoʻomaikaʻi mau ʻana o ke kaʻina hana, ua hoʻomohala ʻia nā kaʻina hana hou e like me ka hoʻoheheʻe ʻana i ka mahu kemika uea wela a me ka hoʻoheheʻe ʻana o ka mahu kemika i kōkua ʻia e ka ion beam.

ʻO nā mea hana kalapona i hoʻololi ʻia i ka uhi ʻana ʻo TaC e komo pū me ka graphite, carbon fiber, a me nā mea hana kalapona/carbon composite. ʻO nā ʻano hana no ka hoʻomākaukau ʻana i ka uhi ʻana o TaC ma ka graphite e pili ana i ka pīpī plasma, CVD, slurry sintering, etc.

ʻO nā mea maikaʻi o ke ʻano CVD: ʻO ke ʻano CVD no ka hoʻomākaukau ʻana i nā uhi TaC e pili ana i ka tantalum halide (TaX5) ma ke ʻano he kumu tantalum a me ka hydrocarbon (CnHm) ma ke kumu kalapona. Ma lalo o kekahi mau kūlana, hoʻoheheʻe ʻia lākou i Ta a me C i kēlā me kēia, a laila e hana pū kekahi me kekahi no ka loaʻa ʻana o nā uhi TaC. Hiki ke hana ʻia ke ʻano CVD ma kahi haʻahaʻa haʻahaʻa, hiki ke pale aku i nā hemahema a me ka hoʻohaʻahaʻa ʻana i nā waiwai mechanical i hoʻokumu ʻia e ka hoʻomākaukau ʻana i ka wela kiʻekiʻe a i ʻole ka mālama ʻana i nā uhi i kekahi ʻano. Hiki ke hoʻopaʻa ʻia ke ʻano a me ke ʻano o ka uhi, a loaʻa iā ia nā pono o ka maʻemaʻe kiʻekiʻe, kiʻekiʻe kiʻekiʻe, a me ka mānoanoa like. ʻO ka mea nui aʻe, hiki ke hoʻolālā ʻia a me ka maʻalahi o ka hoʻonohonoho ʻana a me ke ʻano o nā uhi TaC i hoʻomākaukau ʻia e CVD. ʻO ia ke ʻano oʻo a hoʻohana nui ʻia no ka hoʻomākaukau ʻana i nā pale TaC kiʻekiʻe.

ʻO nā kumu kumu nui o ke kaʻina hana:

A. kinoea kahe holo ana (tantalum kumu, hydrocarbon kinoea e like me carbon kumu, lawe kinoea, dilution kinoea Ar2, hoemi kinoea H2): Ka hoʻololi kinoea holo holo 'ana i ka mana nui ma luna o ka wela kahua, kaomi kahua, a me ke kinoea holo kahua ma. ke keʻena pane, e hoʻololi i ka haku mele, ka hoʻolālā, a me ka hana o ka uhi. ʻO ka hoʻonui ʻana i ke kahe kahe ʻana o Ar e hoʻolohi i ka ulu ʻana o ka uhi a hoʻemi i ka nui o ka palaoa, ʻoiai ʻo ka ratio molar mass o TaCl5, H2, a me C3H6 e pili ana i ka haku ʻana. ʻO ka ratio molar o H2 i TaCl5 (15-20):1, ʻoi aku ka maikaʻi. ʻO ka lākiō molar o TaCl5 a i C3H6 kokoke i ka 3:1. ʻO ka nui o ka TaCl5 a i ʻole C3H6 e hoʻokumu i ka Ta2C a i ʻole ke kalapona manuahi, e pili ana i ka maikaʻi o ka wafer.

B. ʻO ka wela o ka waiho ʻana: ʻO ke kiʻekiʻe o ka wela o ka waiho ʻana, ʻoi aku ka wikiwiki o ka waiho ʻana, ʻoi aku ka nui o ka palaoa, a ʻoi aku ka paʻakikī o ka uhi. Eia kekahi, ʻokoʻa ka mahana a me ka wikiwiki o ka decomposition hydrocarbon i C a me TaCl5 decomposition i Ta, a ʻoi aku ka nui o Ta a me C i Ta2C. Nui ka mana o ka wela ma ka uhi ʻana o TaC i nā mea kalapona i hoʻololi ʻia. Ke piʻi aʻe ka mahana o ka waiho ʻana, piʻi ka nui o ka deposition, piʻi ka nui o ka ʻāpana, a hoʻololi ke ʻano o ke ʻano mai ka spherical a i ka polyhedral. Eia kekahi, ʻoi aku ka kiʻekiʻe o ka wela o ka waiho ʻana, ʻoi aku ka wikiwiki o ka decomposition o TaCl5, ʻoi aku ka liʻiliʻi o ka C manuahi, ʻoi aku ka nui o ke koʻikoʻi i ka uhi ʻana, a maʻalahi nā māwae. Eia nō naʻe, ʻo ka haʻahaʻa haʻahaʻa haʻahaʻa e alakaʻi i ka haʻahaʻa haʻahaʻa o ka hoʻoheheʻe ʻana i ka uhi ʻana, ka lōʻihi o ka manawa waiho ʻana, a ʻoi aku ka nui o nā kumukūʻai maka.

C. Deposition kaomi: Deposition pili pili loa i ka ikehu manuahi o ka ʻili waiwai a e hoʻopilikia i ka manawa noho kinoea i loko o ke keʻena pane, e pili ana i ka wikiwiki o ka nucleation a me ka nui o ka uhi. I ka piʻi ʻana o ke kaomi deposition, ʻoi aku ka lōʻihi o ka noho ʻana o ke kinoea, ʻoi aku ka manawa o nā reactants e hana i ka nucleation reactions, piʻi ka hopena, piʻi ka nui o nā ʻāpana, a ʻoi aku ka mānoanoa o ka uhi; ʻO ka mea ʻē aʻe, e like me ka emi ʻana o ke kaomi deposition, pōkole ka manawa noho kinoea hopena, lohi ka hopena, e liʻiliʻi nā mea liʻiliʻi, a ʻoi aku ka lahilahi o ka uhi ʻana, akā ʻoi aku ka liʻiliʻi o ke kaomi deposition ma ke ʻano aniani a me ke ʻano o ka uhi.

V. Ka ulu ana o ka tantalum carbide coating

ʻOkoʻa ka heluna hoʻonui wela o TaC (6.6×10−6K−1) mai kēlā me nā mea i hoʻopaʻa ʻia i ke kalapona e like me ka graphite, carbon fiber, a me C/C composite material, ka mea e hana ai i nā pale TaC hoʻokahi-phase i hiki ke haki a e haule ana. I mea e hoʻomaikaʻi hou ai i ka ablation a me ka pale ʻana i ka oxidation, ke kūpaʻa mechanical wela kiʻekiʻe, a me ka pale ʻana i ka corrosion kemika kiʻekiʻe o ka uhi ʻana o TaC, ua hana nā mea noiʻi i nā noiʻi e pili ana i nā ʻōnaehana uhi e like me nā ʻōnaehana hoʻopili composite, nā ʻōnaehana hoʻonui i hoʻonui ʻia i ka hopena, a me ka gradient. ʻōnaehana uhi.

ʻO ka ʻōnaehana hoʻopili hui e pani i nā māwae o kahi uhi hoʻokahi. ʻO ka mea maʻamau, hoʻokomo ʻia nā uhi ʻē aʻe i loko o ka ʻili a i ʻole ka papa o loko o TaC e hana i kahi ʻōnaehana hoʻohuihui; ʻo ka ʻōnaehana pale hoʻoikaika paʻa HfC, ZrC, a me nā mea ʻē aʻe, ua like ke ʻano cubic i waena o ke alo e like me TaC, a hiki ke hoʻoheheʻe ʻia nā carbide ʻelua i kekahi i kekahi e hana i kahi ʻano hoʻonā paʻa. ʻAʻohe māwae ka Hf(Ta)C a hoʻopili maikaʻi ʻia i ka mea hui C/C. He maikaʻi ka hana anti-ablation i ka uhi; ʻo ka gradient coating system gradient coating e pili ana i ka ʻāpana o ka uhi ʻana ma kona ʻaoʻao mānoanoa. Hiki i ka hale ke hoʻemi i ke koʻikoʻi o loko, hoʻomaikaʻi i ka like ʻole o nā coefficient hoʻonui wela, a pale i nā māwae.

(II) Tantalum carbide mea hoʻopili mea hana

Wahi a nā helu helu a me nā wanana o QYR (Hengzhou Bozhi), ke kūʻai aku nei ka mākeke hoʻopaʻa carbide coating honua i ka makahiki 2021 a hiki i ka US $ 1.5986 miliona (koe i ka Cree i hana ponoʻī a hoʻolako iā ia iho i nā huahana tantalum carbide coating device), a aia nō ia i ka wā mua. nā pae o ka hoʻomohala ʻoihana.

1. ʻO nā apo hoʻonui kristal a me nā kīʻaha i koi ʻia no ka ulu ʻana o ke aniani: Ma muli o 200 mau kapuahi ulu kristal no kēlā me kēia ʻoihana, ʻo ka māhele mākeke o nā mea i uhi ʻia ʻo TaC i koi ʻia e nā hui ulu kristal 30 ma kahi o 4.7 biliona yuan.

2. Nā pā TaC: Hiki i kēlā me kēia pā ke lawe i 3 wafers, hiki ke hoʻohana ʻia kēlā me kēia pā no 1 mahina, a hoʻopau ʻia ka pā 1 no kēlā me kēia 100 wafers. Pono ʻo 3 miliona wafers i 30,000 TaC trays, kēlā me kēia pā ma kahi o 20,000 mau ʻāpana, a ma kahi o 600 miliona e pono ai i kēlā me kēia makahiki.

3. Nā hiʻohiʻona hōʻemi kalapona ʻē aʻe. E like me ke kiʻekiʻe-mehana kapuahi lining, CVD nozzle, kapuahi paipu, etc., ma kahi o 100 miliona.

Ka manawa hoʻouna: Jul-02-2024