ʻO nā kaʻina hana a pau i ka hana ʻana i kahi chip, ka hopena hope o kawafere ʻoki ʻia i loko o nā pahu pākahi a hoʻopaʻa ʻia i loko o nā pahu liʻiliʻi i hoʻopaʻa ʻia me nā pine liʻiliʻi wale nō. E loiloi ʻia ka chip ma muli o kona paepae, kūpaʻa, nā waiwai o kēia manawa, a me ka volta, akā ʻaʻohe mea e noʻonoʻo i kona ʻano. I ka wā o ke kaʻina hana, hoʻomaʻamaʻa pinepine mākou i ka wafer e hoʻokō i ka planarization pono, ʻoi aku hoʻi no kēlā me kēia kiʻi photolithography. ʻO kawaferPono e palahalaha loa ka ili no ka mea, i ka emi ana o ke kaʻina hana chip, pono ka lens o ka mīkini photolithography e hoʻokō i ka hoʻonā nanometer-scale ma o ka hoʻonui ʻana i ka puka helu (NA) o ka lens. Eia naʻe, hoʻemi kēia i ka hohonu o ka nānā ʻana (DoF). ʻO ka hohonu o ka nānāʻana e pili ana i ka hohonu i loko e hiki ai i ka'ōnaehana optical ke mālama i ka nānā. I mea e maopopo pono ai ke kiʻi photolithography, nā ʻano like ʻole o ka ili o kawaferpono e hāʻule i loko o ka hohonu o ka nānā.

Ma nā ʻōlelo maʻalahi, hāʻawi ka mīkini photolithography i ka hiki ke hoʻomaikaʻi i ka pololei kiʻi. No ka laʻana, loaʻa i nā mīkini kiʻi kiʻi EUV hou he puka helu o 0.55, akā ʻo 45 nanometer wale nō ka hohonu o ka nānā ʻana, me kahi kiʻi kiʻi liʻiliʻi liʻiliʻi i ka wā photolithography. Ina kawaferʻAʻole palahalaha, ʻaʻohe mānoanoa like ʻole, a i ʻole undulations o ka ʻili, e hoʻopilikia ia i ka wā photolithography ma nā wahi kiʻekiʻe a haʻahaʻa.

ʻAʻole ʻo Photolithography wale nō ke kaʻina hana e pono ai ka maʻalahiwaferʻilikai. Nui nā kaʻina hana chip ʻē aʻe e koi i ka wafer polishing. No ka laʻana, ma hope o ka etching pulu, pono ka polishing e hoʻomaʻemaʻe i ka ʻili ʻōpala no ka uhi ʻana a me ka waiho ʻana. Ma hope o ka hoʻokaʻawale ʻana o ka ʻauwaha pāpaʻu (STI), pono ka polishing e hoʻomaʻemaʻe i ka silicon dioxide a hoʻopiha i ka hoʻopiha ʻana i ka ʻauwaha. Ma hope o ka waiho ʻana metala, pono ka polishing e wehe i nā ʻāpana metala keu a pale i nā kaapuni pōkole o ka mīkini.

No laila, ʻo ka hānau ʻana o kahi puʻupuʻu e pili ana i nā ʻanuʻu polina he nui e hōʻemi i ka ʻawaʻawa o ka wafer a me nā ʻano like ʻole o ka ʻili a me ka wehe ʻana i nā mea keu mai ka ʻili. Eia kekahi, ʻike pinepine ʻia nā hemahema o ka ʻili e nā pilikia kaʻina hana ma ka wafer ma hope o kēlā me kēia hana polishing. No laila, ʻo nā ʻenekinia kuleana no ka polishing ke kuleana nui. ʻO lākou nā helu koʻikoʻi i ke kaʻina hana chip a lawe pinepine i ka hewa i nā hālāwai hana. Pono lākou e mākaukau i ka etching pulu a me ka hoʻopuka kino, ʻo ia ke ʻano hana polishing nui i ka hana ʻana i ka chip.

He aha nā ʻano hana poli wafer?

Hiki ke hoʻokaʻawale ʻia nā kaʻina hana polishing i ʻekolu mau ʻāpana nui e pili ana i nā loina pili i waena o ka wai polishing a me ka ʻili wafer silicon:

1. Keʻano hoʻopololei mīkini:

Hoʻopau ʻia ka ʻili o ka ʻili i poni ʻia ma o ka ʻoki ʻana a me ka hoʻololi ʻana i ka plastic no ka loaʻa ʻana o ka ʻili maʻemaʻe. ʻO nā mea hana maʻamau he pōhaku ʻaila, huila huluhulu, a me ka pepa one, i hana mua ʻia e ka lima. Hiki i nā ʻāpana kūikawā, e like me nā ʻili o nā kino kaʻa, hiki ke hoʻohana i nā turntables a me nā mea kōkua ʻē aʻe. No nā papa me nā koina kiʻekiʻe, hiki ke hoʻohana ʻia nā ʻano polishing super-fine. Hoʻohana ʻia ka hoʻoliʻiliʻi maikaʻi loa i nā mea hana abrasive i hana ʻia, ʻo ia hoʻi, i loko o kahi wai polishing abrasive, paʻa i ka ʻili o ka mea hana a hoʻololi ʻia i ka wikiwiki kiʻekiʻe. Hiki i kēia ʻenehana ke hoʻokō i ka ʻili o Ra0.008μm, ka mea kiʻekiʻe loa ma waena o nā ʻano polishing āpau. Hoʻohana mau ʻia kēia ʻano hana no nā molds lens optical.

2. Keʻano hoʻomaʻamaʻa kemika:

ʻO ka polishing kemika e pili ana i ka hoʻoheheʻe ʻia ʻana o nā micro-protrusions ma luna o ka ʻili o nā mea i loko o kahi ʻano kemika, e loaʻa ana ka ʻili maʻemaʻe. ʻO nā pōmaikaʻi nui o kēia ʻano hana ʻo ia ka nele o ka pono o nā mea hana paʻakikī, ka hiki ke hoʻolalelale i nā mea hana paʻakikī, a me ka hiki ke hoʻolalelale i nā mea hana he nui i ka manawa like me ka hana kiʻekiʻe. ʻO ka pilikia nui o ka polishing kemikal ka hoʻokumu ʻana i ka wai polishing. ʻO ka ʻeleʻele o ka ʻili i loaʻa ma ka poli kemika he mau ʻumi micrometers.

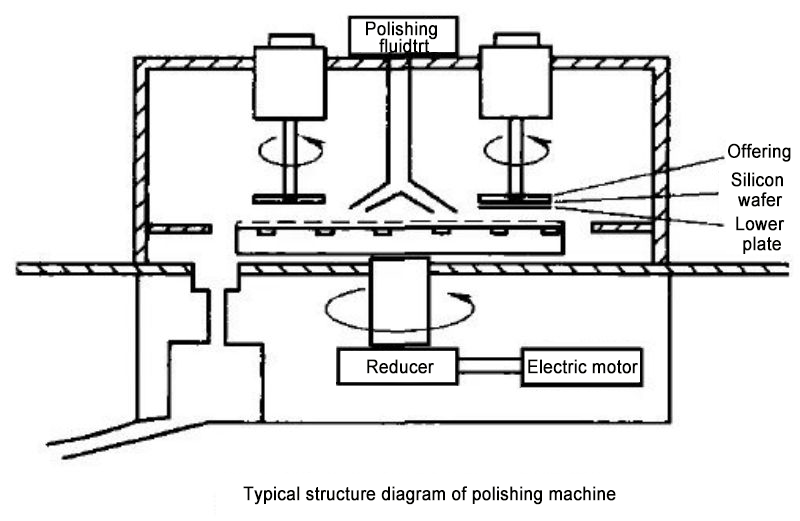

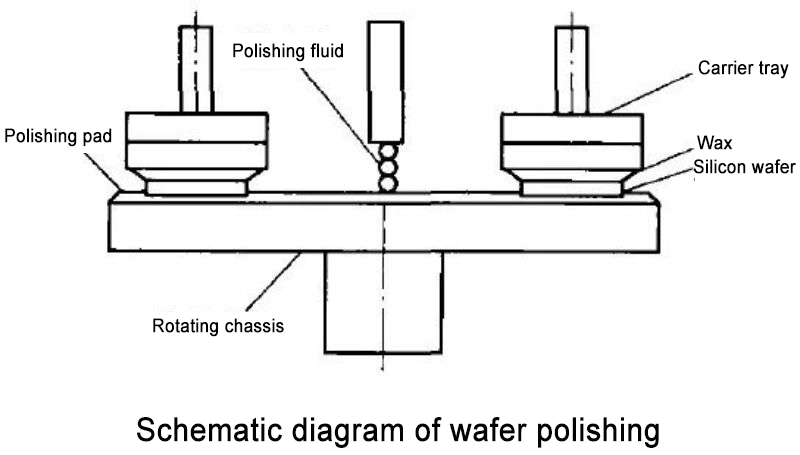

3. Keʻano hana hoʻoliʻiliʻi mechanical (CMP):

Loaʻa i kēlā me kēia o nā ʻano polishing mua ʻelua kona mau pono kūikawā. Hiki i ka hui pū ʻana i kēia mau ʻano ʻelua ke loaʻa nā hopena hoʻohui i ke kaʻina hana. Hoʻohui ʻia ka hoʻoliʻiliʻi kimekini i nā kaʻina hana ʻino a me nā kaʻina hana ʻino. I ka wā o ka CMP, hoʻopaneʻe nā mea hoʻoheheʻe kemika i loko o ka wai polishing i ka mea substrate i poni ʻia, e hana ana i kahi papa oxide palupalu. Hoʻopau ʻia kēia ʻāpana oxide ma o ka hoʻoheheʻe mechanical. ʻO ka hana hou ʻana i kēia oxidation a me ka hana hoʻoneʻe mechanical e hoʻokō pono i ka polishing.

ʻO nā pilikia a me nā pilikia i kēia manawa i ka hoʻolele ʻana i nā mīkini ʻenehana (CMP):

Ke kū nei ʻo CMP i kekahi mau pilikia a me nā pilikia ma nā wahi o ka ʻenehana, ʻoihana waiwai, a me ka hoʻomau kaiapuni:

1) Ke Kaʻina Hana Kūlike: ʻO ka loaʻa ʻana o ke kūpaʻa kiʻekiʻe i ke kaʻina CMP e mau ana ka paʻakikī. ʻOiai i loko o ka laina hana like, hiki i nā ʻano liʻiliʻi liʻiliʻi i nā ʻāpana kaʻina hana ma waena o nā pūʻulu like ʻole a i ʻole nā mea hana e hoʻopilikia i ka kūlike o ka huahana hope.

2) Hiki ke hoʻololi i nā mea hou: Ke hoʻomau nei ka puka ʻana mai o nā mea hou, pono e hoʻololi ka ʻenehana CMP i ko lākou mau ʻano. ʻAʻole kūpono paha kekahi mau mea holomua me nā kaʻina CMP kuʻuna, e koi ana i ka hoʻomohala ʻana i nā wai polishing hiki ke hoʻololi a me nā abrasives.

3) Nā hopena nui: Ke hoʻomau nei ka emi ʻana o nā ʻāpana semiconductor, ʻoi aku ka nui o nā pilikia i hoʻokumu ʻia e nā hopena nui. Pono nā ʻāpana liʻiliʻi i ka palahalaha o ka ʻili, pono i nā kaʻina CMP pololei loa.

4) Ka Mana Hoʻokaʻawale Mea Pono: Ma kekahi mau noi, he mea koʻikoʻi ka hoʻomalu pono ʻana i ka nui o ka lawe ʻana i nā mea no nā mea like ʻole. ʻO ka hōʻoia ʻana i nā helu hoʻoneʻe like ʻole ma nā papa like ʻole i ka wā CMP he mea nui ia no ka hana ʻana i nā mea hana kiʻekiʻe.

5) Aloha Kaiapuni: Loaʻa i nā wai polishing a me nā abrasives i hoʻohana ʻia ma CMP i nā ʻāpana pōʻino. ʻO ka noiʻi a me ka hoʻomohala ʻana i nā kaʻina hana a me nā mea hana CMP e pili ana i ke kaiapuni a hoʻomau.

6) Naʻauao a me Automation: ʻOiai e hoʻomaikaʻi mālie ana ka pae naʻauao a me ka automation o nā ʻōnaehana CMP, pono lākou e hoʻokō i nā kaiapuni hana paʻakikī a loli. ʻO ka loaʻa ʻana o nā kiʻekiʻe kiʻekiʻe o ka automation a me ka nānā ʻana i ka naʻauao e hoʻomaikaʻi ai i ka hana ʻoi aku ka paʻakikī e pono e hoʻoponopono ʻia.

7) Ka Mana Kūʻai: CMP pili i nā lako kiʻekiʻe a me nā kumu waiwai. Pono nā mea hana e hoʻomaikaʻi i ka hana kaʻina hana me ka hoʻoikaika ʻana e hōʻemi i nā kumukūʻai hana e mālama i ka hoʻokūkū mākeke.

Ka manawa hoʻouna: Jun-05-2024