Paipu kapuahi silika carbideLoaʻa i nā mea maikaʻi o ka ikaika kiʻekiʻe, ka paʻakikī kiʻekiʻe, ke kūpaʻa maikaʻi o ka lole, ke kūpaʻa kiʻekiʻe o ka wela, ka pale ʻana i ka corrosion, ke kūpaʻa haʻalulu maikaʻi, ka conductivity thermal kiʻekiʻe, ka pale ʻana i ka oxidation a pēlā aku. Hoʻohana nui ʻia i ka hoʻolei ʻana i ke alapine, ka umu hoʻomaʻamaʻa wela, ka metallurgy, ka ʻoihana kemika, non-ferrous metala forging a me nā ʻoihana ʻē aʻe.Paipu kapuahi silika carbidehoʻohana nui ʻia i ka umu hoʻoheheʻe metallurgical a me ka umu hoʻoheheʻe ʻana i ka umu, a hiki ke hoʻopili ʻia kona lōʻihi e like me nā pono maoli o ka pūnaewele.

Nā hiʻohiʻona opaipu kapuahi silika carbide

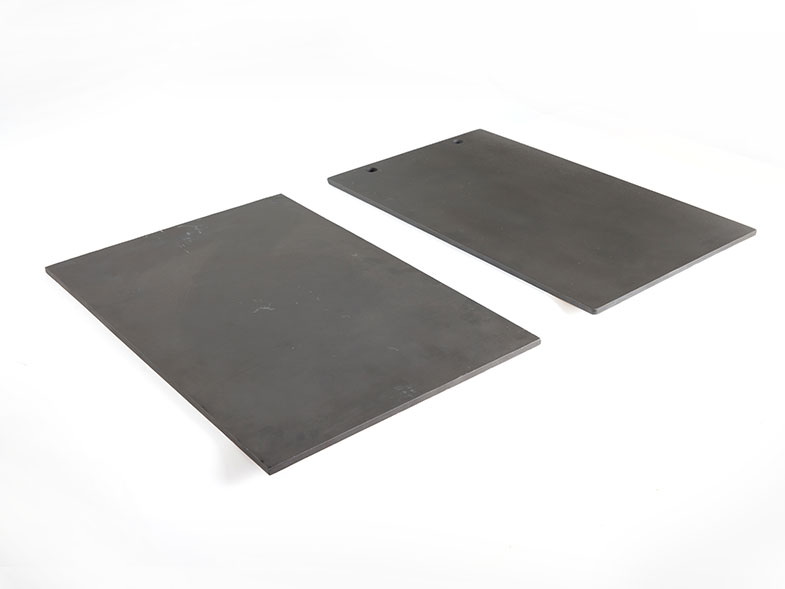

ʻO ka pahu kapuahi silicon carbide kahi huahana maikaʻi loa o ka silicon carbide sintered i ke kiʻekiʻe kiʻekiʻe me ka silicon carbide ma ke ʻano kumu kumu. Loaʻa iā ia nā mea maikaʻi o ke kūpaʻa wela kiʻekiʻe, ka pale ʻana i ka corrosion, ka wikiwiki o ka thermal conductivity, ka ikaika kiʻekiʻe, ka paʻakikī kiʻekiʻe, ke kūpaʻa maikaʻi ʻana, ke kūpaʻa haʻalulu maikaʻi, ka nui o ka thermal conductivity, ke kūpaʻa oxidation maikaʻi a pēlā aku. Hoʻolako ʻia nā ʻaoʻao ʻelua me nā bushings insulation kiʻekiʻe kiʻekiʻe, hiki ke pale maikaʻi ʻia ka ʻino o ka hopena metala i nā mea hoʻomehana uila (me ke koʻokoʻo silicon carbide, uea umu uila, a me nā mea ʻē aʻe) hiki ke pale ʻia, a ʻoi aku ka maikaʻi o nā mea hōʻailona ma mua o nā ʻano huahana graphite āpau . ʻO ka pahu kapuahi silicon carbide he thermal conductivity, oxidation resistance, thermal shock resistance, kiʻekiʻe kiʻekiʻe keʻaʻahu pale pale, maikaʻi kemika kūpaʻa, ikaika ka waika kūʻiʻo, ʻaʻohe hopena i ka waikawa ikaika a me ka alkali.

Paipu kapuahi silika carbideʻenehana hana: ʻo ka huahana i hoʻopau ʻia e lawe i ka carbide silika ma ke ʻano he kumu mua, a he huahana hoʻopau silicon carbide maikaʻi loa i puhi ʻia e ka ʻenehana kūikawā i ka wela kiʻekiʻe. Hiki ke hoʻopilikinoʻia ka laulā lōʻihi e like me nā pono maoli o nā mea kūʻai. ʻO ka hoʻohana nui ʻana o ka pahu umu silika carbide: hoʻohana nui ʻia i ka hoʻomaʻamaʻa metala non-ferrous, ʻōnaehana degasing huahana alumini, paʻi a me nā mīkini kala, zinc a me ka alumini a me ka hoʻopau ʻana i ka huahana.

ʻO ka hoʻomohala ʻana o ka ʻoihana silika carbide

Loaʻa i ka Silicon carbide nā hiʻohiʻona o ka impedance hoʻokomo kiʻekiʻe, haʻahaʻa haʻahaʻa, linearity maikaʻi, a me nā mea ʻē aʻe, ʻo ia kekahi o ka hoʻomohala wikiwiki ʻana i nā mea carbide silicon, a ʻo ka mea mua e hoʻokō i ka ʻoihana. Ke hoʻohālikelike ʻia me MOSFET, ʻaʻohe pilikia hilinaʻi i hoʻokumu ʻia e nā hemahema o ka ʻīpuka oxide a me nā palena o ka neʻe ʻana o ka mea lawe haʻahaʻa, a ʻo kāna mau hiʻohiʻona unipolar e mālama i ka hiki ke hana kiʻekiʻe. Eia kekahi, ʻoi aku ka maikaʻi o ka paʻa a me ka hilinaʻi o ka silicon carbide junction structure i nā wela kiʻekiʻe a ʻoi aku ka maikaʻi o ka volta paepae, ʻo ia hoʻi, ka mea wehe maʻamau, ʻaʻole maikaʻi loa ia no nā noi uila uila, a ʻaʻole kūpono me ka mea maʻamau o kēia manawa. holo kaapuni. Ma ka hoʻokomo ʻana i ka ʻenehana o ka mea hoʻoheheʻe groove, ua hoʻomohala ʻia ka mea hoʻonui ma lalo o ke kūlana maʻamau. Eia nō naʻe, hoʻokumu pinepine ʻia nā mea hana i hoʻonui ʻia me ka uku o kekahi mau hiʻohiʻona kūʻē kūʻē, no laila ʻoi aku ka maʻalahi o ka wehe ʻana (depletion type) e hoʻokō i ka nui o ka mana kiʻekiʻe a me ka mana o kēia manawa, a hiki ke loaʻa ke ʻano depletion ma ka hoʻokaʻawale ʻana i ke kūlana hana. Hoʻokō ʻia ke ʻano cascade ma o kahi moʻo o MOSFET e pili ana i ke kilika haʻahaʻa haʻahaʻa. ʻO ke kaapuni kaʻa kaʻa kaʻa kaʻa i kūpono maoli me ke kaʻapuni kaʻa kaʻa uila. He kūpono loa kēia ʻano cascade no ka hoʻololi ʻana i ka silikoni kumu i nā manawa kiʻekiʻe-volt a me ka mana kiʻekiʻe, a pale pololei i ka pilikia hoʻohālikelike o ke kaʻa kaʻa.

Ka manawa hoʻouna: Sep-25-2023