He aha ka Silicon Carbide SiC Coating?

ʻO ka uhi ʻana o Silicon Carbide (SiC) kahi ʻenehana hoʻololi e hāʻawi i ka pale a me ka hana ʻokoʻa i nā kaiapuni kiʻekiʻe a me nā kemika. Hoʻohana ʻia kēia hoʻopiʻi kiʻekiʻe i nā mea like ʻole, me ka graphite, ceramics, a me nā metala, e hoʻomaikaʻi i ko lākou mau waiwai, e hāʻawi ana i ka pale maikaʻi loa mai ka corrosion, oxidation, a me ka lole. ʻO nā waiwai kūʻokoʻa o nā ʻāpana SiC, me ko lākou maʻemaʻe kiʻekiʻe, ka conductivity thermal maikaʻi loa, a me ka paʻa ʻana o ka hoʻolālā ʻana, e kūpono iā lākou no ka hoʻohana ʻana i nā ʻoihana e like me ka hana semiconductor, aerospace, a me nā ʻenehana hoʻomehana kiʻekiʻe.

ʻO nā pōmaikaʻi o ka uhi ʻana i ka silika carbide

Hāʻawi ʻo SiC coating i nā pono nui e hoʻokaʻawale iā ia mai nā pale pale kuʻuna:

- -Ke Kū'ē Kū'ē a me ka Corrosion

- ʻO ka ʻōnaehana cubic SiC e hōʻoiaʻiʻo i ka uhi kiʻekiʻe kiʻekiʻe, hoʻomaikaʻi nui i ka pale ʻana i ka corrosion a hoʻonui i ke ola o ka mea.

- -Ka uhi ʻokoʻa o nā ʻano paʻakikī

- Kaulana ʻo SiC coating no kāna uhi maikaʻi loa, ʻoiai i loko o nā puka makapō liʻiliʻi me ka hohonu a hiki i 5 mm, e hāʻawi ana i ka mānoanoa like ʻole a hiki i 30% ma kahi hohonu loa.

- -Ka ʻili ʻili hiki ke hoʻololi ʻia

- Hiki ke hoʻololi ʻia ke kaʻina hana uhi, hiki ke hoʻololi i ka ʻili o ka ʻili e kūpono i nā koi noi.

- -ʻO ka hoʻomaʻemaʻe kiʻekiʻe

- Loaʻa ma o ka hoʻohana ʻana i nā kinoea maʻemaʻe kiʻekiʻe, ʻoi aku ka maʻemaʻe o ka uhi SiC, me nā pae haumia ma lalo o 5 ppm. He mea nui kēia maʻemaʻe no nā ʻoihana ʻenehana kiʻekiʻe e koi ana i ka pololei a me ka liʻiliʻi o ka haumia.

- -Hoʻopaʻa wela

- Hiki i ka silicone carbide ceramic coating ke kū i nā mahana wela, me ka mahana hana kiʻekiʻe a hiki i 1600 ° C, e hōʻoiaʻiʻo ana i ka hilinaʻi i nā wahi wela kiʻekiʻe.

Nā noi o ka SiC Coating

Hoʻohana nui ʻia nā uhi SiC ma nā ʻoihana like ʻole no kā lākou hana like ʻole i nā kaiapuni paʻakikī. Loaʻa nā noi nui:

- -ʻOihana LED & Solar

- Hoʻohana ʻia ka uhi no nā ʻāpana i ka hana ʻana o ka LED a me ka solar cell, kahi e pono ai ka hoʻomaʻemaʻe kiʻekiʻe a me ka pale wela.

- -Kiʻekiʻe-Mahana Pumehana ʻenehana

- Hoʻohana ʻia ʻo SiC-coated graphite a me nā mea ʻē aʻe i nā mea hoʻomehana no nā umu ahi a me nā reactors i hoʻohana ʻia i nā kaʻina hana ʻenehana.

- -ʻO Semiconductor Crystal Growth

- I ka ulu ʻana o ke aniani semiconductor, hoʻohana ʻia nā uhi SiC no ka pale ʻana i nā mea e pili ana i ka ulu ʻana o ke silikoni a me nā kristal semiconductor ʻē aʻe, e hāʻawi ana i ke kūpaʻa corrosion kiʻekiʻe a me ke kūpaʻa wela.

- -Silicon a me SiC Epitaxy

- Hoʻopili ʻia nā ʻāpana SiC i nā ʻāpana i ke kaʻina ulu epitaxial o ke silikoni a me ka silicon carbide (SiC). Ke pale nei kēia mau uhi i ka oxidation, contamination, a hōʻoia i ka maikaʻi o nā papa epitaxial, he mea koʻikoʻi ia no ka hana ʻana i nā mea hana semiconductor kiʻekiʻe.

- - Nā Kaʻina Oxidation a me Diffusion

- Hoʻohana ʻia nā ʻāpana SiC-coated i nā kaʻina oxidation a me ka diffusion, kahi e hāʻawi ai lākou i kahi pale kūpono e kūʻē i nā haumia makemake ʻole a hoʻonui i ka pono o ka huahana hope. Hoʻomaikaʻi nā uhi i ka lōʻihi a me ka hilinaʻi o nā ʻāpana i hōʻike ʻia i ka oxidation kiʻekiʻe a i ʻole ka diffusion.

Nā waiwai nui o ka SiC Coating

Hāʻawi ʻo SiC coatings i kahi ʻano waiwai e hoʻomaikaʻi i ka hana a me ka lōʻihi o nā ʻāpana sic coated:

- -Kōnaehana Crystal

- Hana ʻia ka uhi me ka aβ 3C (cubic) anianihale, he isotropic a hāʻawi i ka pale corrosion maikaʻi loa.

- -Ke kiʻekiʻe a me ka Porosity

- Loaʻa i nā pale SiC ka mānoanoa o3200 kg/m³a hōʻike0% porosity, hōʻoia i ka helium leak-paʻa i ka hana a me ka maikaʻi o ka corrosion.

- -ʻO nā mea wela a me ka uila

- He kiʻekiʻe ka hoʻoili wela o ka SiC(200 W/m·K)a me ka maikaʻi o ka pale ʻana i ka uila(1MΩ·m), i mea kūpono no nā noi e koi ana i ka mālama ʻana i ka wela a me ka insulation uila.

- -Ka Ikaika Mechanical

- Me ka modulus elastic o450 GPa, Hāʻawi nā ʻāpana SiC i ka ikaika mechanical ʻoi aku ka maikaʻi, e hoʻonui ai i ka paʻa o nā ʻāpana.

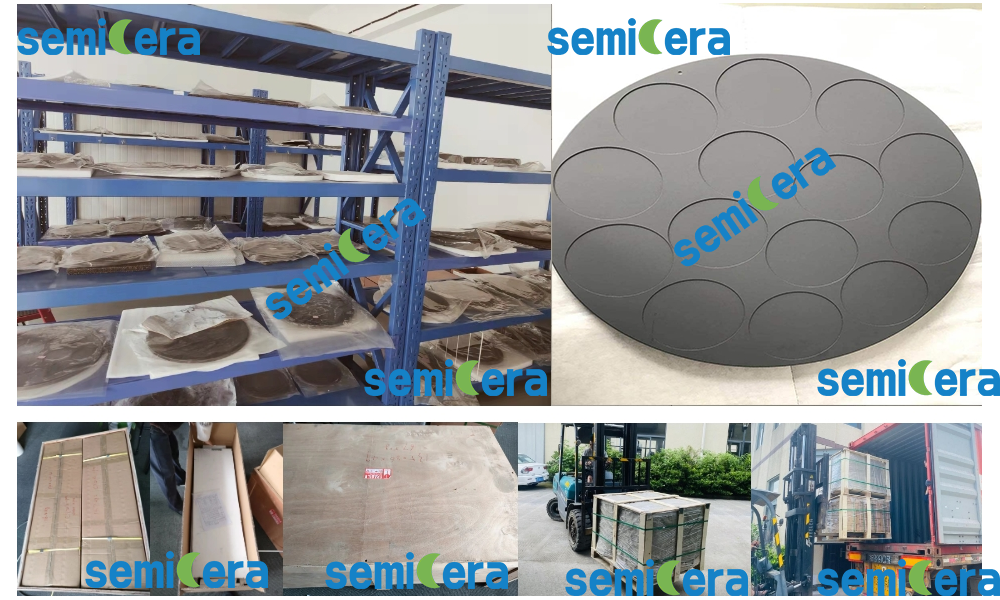

SiC silikon carbide kaʻina hana

Hoʻohana ʻia ka uhi SiC ma o Chemical Vapor Deposition (CVD), kahi kaʻina hana e pili ana i ka decomposition thermal o nā kinoea e waiho i nā ʻāpana SiC lahilahi ma ka substrate. Hāʻawi kēia ʻano deposition i ka ulu kiʻekiʻe a me ka mana pololei ma luna o ka mānoanoa papa, hiki ke hele mai10 µm a i 500 µm, ma muli o ka noi. ʻO ke kaʻina hana uhi e hōʻoiaʻiʻo i ka uhi ʻokoʻa, ʻoiai ma nā geometries paʻakikī e like me nā lua liʻiliʻi a hohonu paha, he mea paʻakikī loa ia no nā ʻano uhi kuʻuna.

Nā mea kūpono no ka uhi ʻana o SiC

Hiki ke hoʻopili ʻia nā ʻāpana SiC i nā ʻano mea like ʻole, me:

- -Graphite a me Carbon Composite

- ʻO Graphite kahi substrate kaulana no ka uhi ʻana o SiC ma muli o kāna mau waiwai wela a me nā uila. Hoʻopili ʻo SiC coating i ka hana porous o ka graphite, e hana ana i kahi paʻa i hoʻonui ʻia a hāʻawi i ka pale ʻoi aku ka maikaʻi.

- -Keramika

- ʻO nā seramika i hoʻokumu ʻia i ka silikon e like me SiC, SiSiC, a me RSiC e pōmaikaʻi mai nā uhi SiC, kahi e hoʻomaikaʻi ai i ko lākou pale ʻana i ka corrosion a pale i ka laha ʻana o nā haumia.

No ke aha e koho ai i ka SiC Coating?

Hāʻawi ka uhi ʻana o ka ʻili i kahi hopena ākea a maikaʻi hoʻi no nā ʻoihana e koi ana i ka maʻemaʻe kiʻekiʻe, ka pale ʻana i ka corrosion, a me ke kūpaʻa wela. Inā ʻoe e hana ana i ka semiconductor, aerospace, a i ʻole nā hana hoʻomehana kiʻekiʻe, hāʻawi nā pale SiC i ka pale a me ka hana āu e pono ai e mālama i ka maikaʻi o ka hana. ʻO ka hui pū ʻana o ka hoʻolālā cubic kiʻekiʻe, nā waiwai o ka ʻili i hana ʻia, a me ka hiki ke hoʻopaʻa i nā geometries paʻakikī e hōʻoia i nā mea i uhi ʻia ʻo sic hiki ke kū i nā kaiapuni paʻakikī loa.

No ka ʻike hou aku a i ʻole ke kūkākūkā ʻana pehea e pōmaikaʻi ai ka uhi silicon carbide ceramic i kāu noi kikoʻī, e ʻoluʻolukāhea iā mā˚ou.

Ka manawa hoʻouna: ʻAukake-12-2024