ʻO nā seramika silikoni nitride (Si₃N₄), e like me nā seramika hoʻolālā kiʻekiʻe, loaʻa nā waiwai maikaʻi e like me ke kūpaʻa kiʻekiʻe o ka wela, ka ikaika kiʻekiʻe, ka paʻakikī kiʻekiʻe, ka paʻakikī kiʻekiʻe, ke kūpaʻa creep, ka pale ʻana i ka oxidation, a me ke kūpaʻa ʻaʻahu. Hoʻohui ʻia, hāʻawi lākou i ke kūpaʻa haʻalulu wela maikaʻi, nā waiwai dielectric, ka conductivity thermal kiʻekiʻe, a me ka hana hoʻoili hawewe electromagnetic kiʻekiʻe kiʻekiʻe. Hoʻohana nui ʻia kēia mau waiwai piha koʻikoʻi i nā mea hana paʻakikī, ʻoi aku hoʻi i ka aerospace a me nā ʻoihana ʻenehana kiʻekiʻe.

Eia nō naʻe, ʻo Si₃N₄, he hui pū me nā mea paʻa covalent ikaika, he hale paʻa ka mea e paʻakikī ai ka hoʻopaʻa ʻana i ke kiʻekiʻe kiʻekiʻe ma o ka diffusion solid-state wale nō. No ka hoʻolaha ʻana i ka sintering, hoʻohui ʻia nā mea kōkua sintering, e like me nā metala oxides (MgO, CaO, Al₂O₃) a me nā oxides earth oxides (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), i hoʻohui ʻia e hoʻomaʻamaʻa i ka densification ma o kahi mīkini hoʻoheheʻe wai.

I kēia manawa, ke neʻe nei ka ʻenehana mīkini semiconductor honua i nā voltage kiʻekiʻe, nā au nui, a me ka nui o ka mana. He nui ka noiʻi ʻana i nā ʻano hana no ka hana ʻana i nā seramika Si₃N₄. Hoʻopuka kēia ʻatikala i nā kaʻina hana sintering e hoʻomaikaʻi maikaʻi i ka nui a me nā waiwai mechanical piha o ka silicon nitride ceramics.

Nā ʻano hana hoʻoheheʻe maʻamau no nā seramika Si₃N₄

Hoʻohālikelike o ka hana ʻana no ka Si₃N₄ Ceramics i hoʻomākaukau ʻia e nā ʻano Sintering ʻokoʻa.

1. ʻO ka hoʻopaʻa inoa ʻana (RS):ʻO ka sintering reactive ke ʻano mua i hoʻohana ʻia no ka hoʻomākaukau ʻana i nā seramika Si₃N₄. He mea maʻalahi, kūpono ke kumu kūʻai, a hiki ke hana i nā ʻano paʻakikī. Eia nō naʻe, he pōʻai hana lōʻihi kona, ʻaʻole kūpono i ka hana ʻenehana.

2. Hoʻopaʻa Paʻa ʻole (PLS):ʻO kēia ke kaʻina hana sintering maʻamau a maʻalahi. Eia nō naʻe, pono ia i ka Si₃N₄ kiʻekiʻe i nā mea maka a loaʻa pinepine i nā seramika me ka haʻahaʻa haʻahaʻa, ka emi ʻana nui, a me ke ʻano o ka pohā a i ʻole ke ʻano.

3. Hoʻopaʻa Paʻi Wela (HP):ʻO ka hoʻohana ʻana o ka uniaxial mechanical pressure e hoʻonui i ka ikaika hoʻokele no ka sintering, e ʻae ana i nā ceramics dense e hana ʻia ma nā mahana 100-200 ° C haʻahaʻa ma mua o nā mea i hoʻohana ʻia i ka sintering pressureless. Hoʻohana pinepine ʻia kēia ʻano hana no ka hana ʻana i nā seramika maʻalahi akā paʻakikī ke hoʻokō i ka mānoanoa a me nā koi no nā mea substrate.

4. Spark Plasma Sintering (SPS):Hōʻike ʻia ka SPS e ka sintering wikiwiki, hoʻomaʻemaʻe palaoa, a me ka hoʻohaʻahaʻa ʻana i nā mahana sintering. Eia nō naʻe, koi ʻo SPS i ka waiwai nui i nā mea hana, a ʻo ka hoʻomākaukau ʻana i ka conductivity thermal kiʻekiʻe Si₃N₄ ceramics ma o SPS aia nō i ka pae hoʻokolohua a ʻaʻole naʻe i hana ʻia.

5. Hoʻopili ʻia ke kinoea-Pressure Sintering (GPS):Ma ka hoʻohana ʻana i ke kaomi kinoea, ʻaʻole kēia ʻano hana i ka decomposition ceramic a me ka pohō kaumaha ma nā wela kiʻekiʻe. ʻOi aku ka maʻalahi o ka hana ʻana i nā seramika kiʻekiʻe a hiki i ka hana pūʻulu. Eia nō naʻe, paʻakikī ke kaʻina hana hoʻoheheʻe kinoea hoʻokahi ʻanuʻu e hana i nā ʻāpana me ka waihoʻoluʻu o loko a me waho. ʻO ka hoʻohana ʻana i kahi kaʻina sintering ʻelua a i ʻole ka nui-step hiki ke hōʻemi nui i ka ʻike o ka oxygen intergranular, hoʻomaikaʻi i ka conductivity thermal, a hoʻonui i nā waiwai holoʻokoʻa.

Eia naʻe, ʻo ke kiʻekiʻe o ka sintering kiʻekiʻe o ʻelua mau ʻanuʻu kinoea-press sintering ua alakaʻi i ka noiʻi mua e kālele nui ʻia i ka hoʻomākaukau ʻana i nā substrates ceramic Si₃N₄ me ka conductivity thermal kiʻekiʻe a me ka ikaika kulou wela o ka lumi. ʻO ka noiʻi ʻana ma ka Si₃N₄ ceramics me nā waiwai mechanical piha a me nā waiwai mechanical wela kiʻekiʻe he palena palena.

ʻO ke ʻano hoʻoheheʻe ʻana o ke kinoea ʻelua ʻanuʻu no Si₃N₄

Ua hoʻohana ʻo Yang Zhou a me nā hoa hana mai Chongqing University of Technology i kahi ʻōnaehana kōkua sintering o 5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ no ka hoʻomākaukau ʻana i nā ceramics Si₃N₄ me ka hoʻohana ʻana i nā kaʻina hana hoʻoheheʻe kinoea a me ʻelua ʻanuʻu ma 1800°C. ʻO nā seramika Si₃N₄ i hana ʻia e ke kaʻina sintering ʻelua ʻanuʻu, ʻoi aku ka kiʻekiʻe a me ka ʻoi aku ka maikaʻi o nā waiwai mechanical piha. Hōʻuluʻulu kēia i nā hopena o nā kaʻina hana hoʻoheheʻe kinoea a me ʻelua ʻanuʻu i ka microstructure a me nā waiwai mechanical o nā ʻāpana ceramic Si₃N₄.

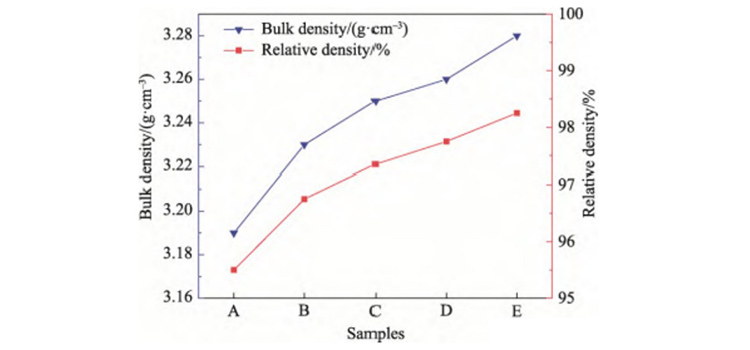

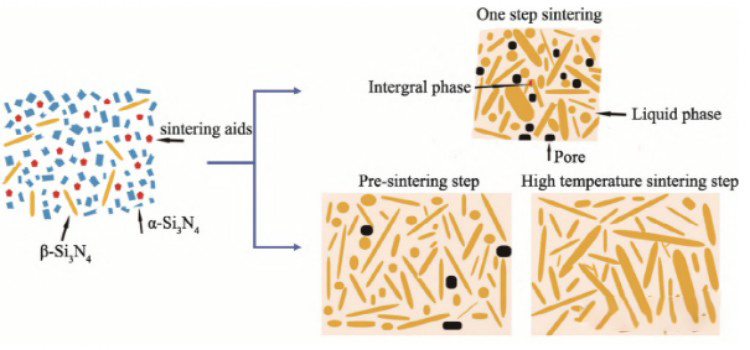

Density ʻO ke kaʻina hana densification o Si₃N₄ maʻamau e pili ana i ʻekolu mau ʻanuʻu, me ka uhi ʻana ma waena o nā pae. ʻO ka pae mua, ka hoʻonohonoho hou ʻana i nā ʻāpana, a me ka pae ʻelua, ka dissolution-precipitation, ʻo ia nā pae koʻikoʻi no ka hoʻopaʻa ʻana. ʻO ka manawa pane kūpono i kēia mau ʻanuʻu e hoʻomaikaʻi nui ai i ka nui o ka hāpana. Ke hoʻonohonoho ʻia ka mahana ma mua o ka hoʻomaʻamaʻa ʻana no ke kaʻina hana sintering ʻelua i ka 1600 ° C, hana ʻo β-Si₃N₄ grains i kahi anga a hana i nā pores pani. Ma hope o ka hoʻomaʻamaʻa mua ʻana, hoʻomehana hou ʻia ma lalo o ke kiʻekiʻe kiʻekiʻe a me ke kaomi nitrogen e hoʻoikaika i ka kahe wai-phase a me ka hoʻopiha ʻana, e kōkua ana i ka hoʻopau ʻana i nā pores i pani ʻia, e hoʻomaikaʻi hou i ka density o nā seramika Si₃N₄. No laila, ʻo nā laʻana i hana ʻia e ke kaʻina hana hoʻoheheʻe ʻelua ʻanuʻu e hōʻike i ke kiʻekiʻe kiʻekiʻe a me ka nui pili ma mua o nā mea i hana ʻia e ka sintering hoʻokahi.

Māhele a me ka Microstructure I ka hoʻoheheʻe ʻana i hoʻokahi ʻanuʻu, ua kaupalena ʻia ka manawa i loaʻa no ka hoʻonohonoho hou ʻana o nā ʻāpana a me ka hoʻopuehu ʻana i ka palena o ka palaoa. Ma ke kaʻina hana sintering ʻelua, hana ʻia ka hana mua ma ka haʻahaʻa haʻahaʻa a me ke kaomi kinoea haʻahaʻa, e hoʻolōʻihi i ka manawa hoʻonohonoho hou a loaʻa i nā hua nui. A laila hoʻonui ʻia ka mahana i ka pae wela kiʻekiʻe, kahi e hoʻomau ai ka ulu ʻana o nā kīʻaha ma o ke kaʻina oʻo ʻo Ostwald, e hāʻawi ana i nā seramika Si₃N₄ kiʻekiʻe.

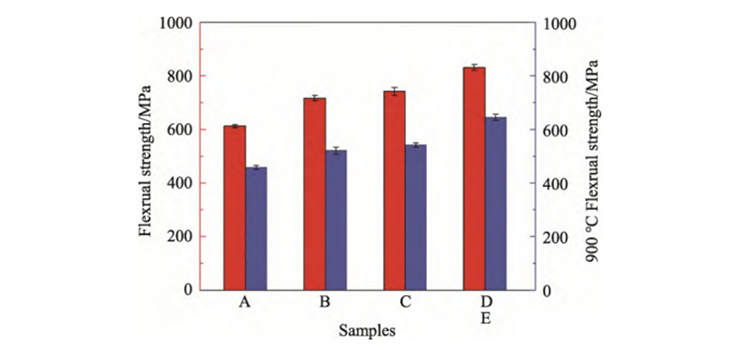

Nā Pono Mechanical ʻO ka palupalu o ka māhele intergranular i nā mahana kiʻekiʻe ke kumu nui o ka ikaika hoʻemi. I ka hoʻoheheʻe ʻana i hoʻokahi ʻanuʻu, hana ʻia ka ulu ʻana o ka palaoa maʻamau i nā pores liʻiliʻi ma waena o nā kīʻaha, kahi e pale ai i ka hoʻomaikaʻi nui ʻana i ka ikaika wela. Eia naʻe, i loko o ke kaʻina hana sintering ʻelua ʻanuʻu, ʻo ka māhele aniani, i hoʻokaʻawale ʻia i loko o nā palena o ka palaoa, a me nā ʻano like ʻole e hoʻonui i ka ikaika intergranular, e hopena i ka ikaika bending kiʻekiʻe.

I ka hopena, hiki i ka hoʻopaʻa lōʻihi ʻana i ka sintering hoʻokahi ke hoʻohaʻahaʻa pono i ka porosity kūloko a loaʻa i ke kala o loko a me ke ʻano like ʻole akā hiki ke alakaʻi i ka ulu ʻana o ka palaoa, e hoʻohaʻahaʻa i kekahi mau waiwai mechanical. Ma ka hoʻohana ʻana i kahi kaʻina hana sintering ʻelua-ka hoʻohana ʻana i ka haʻahaʻa haʻahaʻa pre-sintering e hoʻolōʻihi i ka manawa hoʻonohonoho hou a me ka paʻa ʻana i ka wela kiʻekiʻe e hāpai i ka ulu ʻana o ka palaoa like ʻole-he Si₃N₄ ceramic me ka 98.25% pili, ka microstructure like ʻole, a me nā waiwai mechanical piha maikaʻi. hiki ke hoʻomākaukau maikaʻi ʻia.

| inoa | Pāpaʻa | ʻO ka papa epitaxial haku mele | Kaʻina hana epitaxial | Mea epitaxial |

| Silicon homepitaxial | Si | Si | Epitaxy Māhele Māmā (VPE) | SiCl4+H2 |

| Silicon heteroepitaxial | Sapphire a spinel paha | Si | Epitaxy Māhele Māmā (VPE) | SiH₄+H₂ |

| GaAs homepitaxial | GaAs | GaAs GaAs | Epitaxy Māhele Māmā (VPE) | AsCl₃+Ga+H₂ (Ar) |

| GaAs | GaAs GaAs | Molecular Beam Epitaxy (MBE) | Ga+As | |

| GaAs heteroepitaxial | GaAs GaAs | GaAlAs/GaAs/GaAlAs | Epitaxy Māhele Waiwai (LPE) ʻAha Moku (VPE) | Ga+Al+CaAs+ H2 Ga+AsH3+PH3+CHl+H2 |

| GaP homepitaxial | GaP | GaP(GaP;N) | Epitaxy Māhele Waiwai (LPE) Epitaxy Māhele Waiwai (LPE) | Ga+GaP+H2+(NH3) Ga+GaAs+GaP+NH3 |

| ʻO Superlattice | GaAs | GaAlAs/GaAs (pōkole) | Molecular Beam Epitaxy (MBE) MOCVD | Ca,As,Al GaR₃+AlR3+AsH3+H2 |

| InP homoepitaxial | InP | InP | Epitaxy Māhele Māmā (VPE) Epitaxy Māhele Waiwai (LPE) | PCl3+In+H2 In+InAs+GaAs+InP+H₂ |

| Epitaxy Si/GaAs | Si | GaAs | Molecular Beam Epitaxy (MBE) MOGVD | ʻO Ga、As GaR₃+AsH₃+H₂ |

Ka manawa hoʻouna: Dec-24-2024