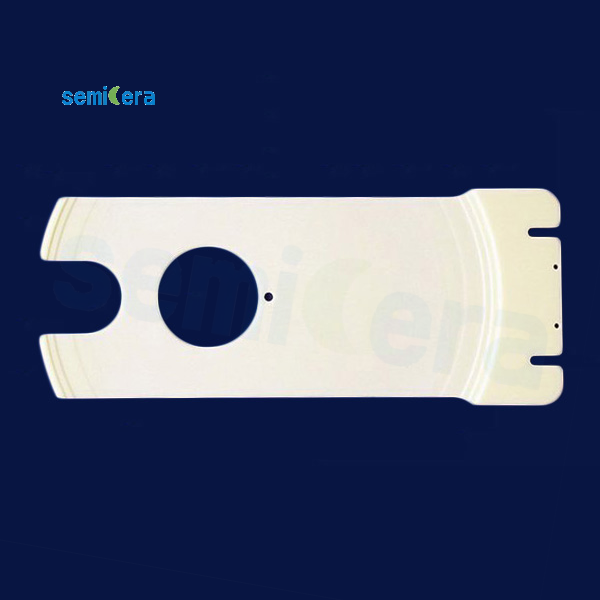

ʻO Semicera's Silicon On Insulator (SOI) Wafer ka mea mua o ka hana hou semiconductor, e hāʻawi ana i ka hoʻokaʻawale uila i hoʻonui ʻia a me ka hana wela maikaʻi. ʻO ka hoʻolālā SOI, i loaʻa i kahi papa silika lahilahi ma kahi substrate insulating, hāʻawi i nā pono koʻikoʻi no nā mea uila hana kiʻekiʻe.

Hoʻolālā ʻia kā mākou mau wafers SOI e hōʻemi i ka capacitance parasitic a me nā au leakage, he mea nui ia no ka hoʻomohala ʻana i nā kaapuni hoʻohui kiʻekiʻe a me ka mana haʻahaʻa. ʻO kēia ʻenehana holomua e hōʻoia i ka hana ʻoi aku ka maikaʻi o nā hāmeʻa, me ka wikiwiki a me ka hoʻemi ʻana i ka ikehu, koʻikoʻi no nā uila uila hou.

ʻO nā kaʻina hana kiʻekiʻe i hoʻohana ʻia e Semicera e hōʻoiaʻiʻo i ka hana ʻana o nā wafers SOI me ka kūlike a me ka kūlike. He mea koʻikoʻi kēia ʻano no nā noi ma ke kelepona, automotive, a me nā mea hoʻohana uila, kahi e pono ai nā ʻāpana hilinaʻi a kiʻekiʻe.

Ma waho aʻe o kā lākou mau pono uila, hāʻawi ka Semicera's SOI wafers i ka insulation thermal kiʻekiʻe, e hoʻonui ana i ka hoʻoheheʻe wela a me ka paʻa i nā mea kiʻekiʻe a me nā mana kiʻekiʻe. He waiwai nui kēia hiʻohiʻona i nā noi e pili ana i ka hana wela nui a koi i ka hoʻokele wela kūpono.

Ma ke koho ʻana iā Semicera's Silicon On Insulator Wafer, hoʻopukapuka ʻoe i kahi huahana e kākoʻo ana i ka holomua o nā ʻenehana ʻokiʻoki. ʻO kā mākou kūpaʻa i ka maikaʻi a me ka hana hou e hōʻoia i ka hoʻokō ʻana o kā mākou wafer SOI i nā koi koʻikoʻi o ka ʻoihana semiconductor o kēia lā, e hāʻawi ana i ke kumu no nā mea uila e hiki mai ana.

| Nā mea | Paahana | Ka noiʻi | Dummy |

| Nā Kūlana Crystal | |||

| Polytype | 4H | ||

| Ua hewa ka hoʻonohonoho ʻana o ka ʻili | <11-20 >4±0.15° | ||

| Nā Kūlana Uila | |||

| Dopant | n-ʻano Nitrogen | ||

| Kū'ē | 0.015-0.025ohm·cm | ||

| Nā Kūlana Mechanical | |||

| Anawaena | 150.0±0.2mm | ||

| mānoanoa | 350±25 μm | ||

| Kūlana pālahalaha mua | [1-100]±5° | ||

| Ka lōʻihi pālahalaha mua | 47.5±1.5mm | ||

| palahalaha lua | ʻAʻohe | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Kakaka | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| 'Oka (AFM) mua (Si-maka) | Ra≤0.2nm (5μm*5μm) | ||

| Hoʻolālā | |||

| Micropipe mānoanoa | <1 ea/cm2 | <10 ea/cm2 | <15 ea/cm2 |

| Metala haumia | ≤5E10atoms/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| ʻAno o mua | |||

| Imua | Si | ||

| Hoʻopau ʻili | Si-maka CMP | ||

| Nā ʻāpana | ≤60ea/wafer (nui≥0.3μm) | NA | |

| Nā ʻōpala | ≤5ea/mm. Ka lōʻihi huila ≤Diameter | ʻO ka lōʻihi huila≤2*Diameter | NA |

| ʻAlani ʻili/mau lua/ʻeleʻele/striations/ māwae/contamination | ʻAʻohe | NA | |

| Nā ʻāpana lihi/indents/fracture/papa hex | ʻAʻohe | ||

| Nā wahi polytype | ʻAʻohe | ʻĀpana huila≤20% | ʻĀpana huila≤30% |

| Hōʻailona laser mua | ʻAʻohe | ||

| ʻAno o hope | |||

| Hoʻopau hope | C-maka CMP | ||

| Nā ʻōpala | ≤5ea / mm, Ka lōʻihi huila≤2 * Anawaena | NA | |

| Nā hemahema o hope (nā ʻāpana lihi/indents) | ʻAʻohe | ||

| ʻōkalakala kua | Ra≤0.2nm (5μm*5μm) | ||

| Hōʻailona laser hope | 1 mm (mai ka lihi luna) | ||

| Kaulana | |||

| Kaulana | Chamfer | ||

| Hoʻopili ʻia | |||

| Hoʻopili ʻia | Epi-mākaukau me ka hoʻopaʻa ʻumeke Puke cassette nui-wafer | ||

| *Nā memo: "NA" ʻo ia hoʻi, ʻaʻohe noi ʻO nā mea i ʻōlelo ʻole ʻia e pili ana i SEMI-STD. | |||