Hoʻomaka i ka CVD TaC Coating:

ʻO ka CVD TaC Coating kahi ʻenehana e hoʻohana ana i ka hoʻoheheʻe ʻana i ka mahu kemika e waiho i ka uhi tantalum carbide (TaC) ma ka ʻili o kahi substrate. ʻO ka Tantalum carbide kahi mea hana kiʻekiʻe me ka mechanical a me nā waiwai kemika. Hoʻokumu ka hana CVD i kahi kiʻiʻoniʻoni TaC like ʻole ma ka ʻili o ka substrate ma o ka hopena kinoea.

Nā hiʻohiʻona nui:

ʻO ka paʻakikī maikaʻi loa a me ke kūpaʻa ʻaʻahu: He kiʻekiʻe loa ka paʻakikī o ka Tantalum carbide, a hiki i ka CVD TaC Coating ke hoʻomaikaʻi nui i ka pale ʻana o ka substrate. ʻO kēia ka mea i kūpono i ka uhi no nā noi ma nā wahi lole kiʻekiʻe, e like me nā mea hana ʻoki a me nā mold.

Kūpaʻa wela kiʻekiʻe: Hoʻomalu nā uhi TaC i ka umu koʻikoʻi a me nā ʻāpana reactor i nā mahana a hiki i 2200 ° C, e hōʻike ana i ka paʻa maikaʻi. Mālama ʻo ia i ka paʻa kemika a me ka mīkini ma lalo o nā kūlana wela loa, kūpono ia no ka hoʻoili ʻana i ka wela kiʻekiʻe a me nā noi i nā wahi wela kiʻekiʻe.

Paʻa kemika maikaʻi loa: Loaʻa i ka Tantalum carbide ke kūpaʻa ʻino i ka hapa nui o nā waikawa a me nā alkalis, a hiki i ka CVD TaC Coating ke pale pono i ka hōʻino ʻana i ka substrate i nā wahi corrosive.

Kiekie hehee ai: Loaʻa i ka Tantalum carbide kahi helu heheʻe kiʻekiʻe (ma kahi o 3880 ° C), hiki ke hoʻohana ʻia ka CVD TaC Coating i nā kūlana wela kiʻekiʻe loa me ka hoʻoheheʻe ʻole a hoʻohaʻahaʻa paha.

ʻOi aku ka maikaʻi o ka thermal conductivity: He kiʻekiʻe ka wela o ka uhi ʻana o TaC, e kōkua ana i ka hoʻopau maikaʻi ʻana i ka wela i nā kaʻina hana wela kiʻekiʻe a pale i ka wela nui kūloko.

Nā noi kūpono:

• ʻO Gallium Nitride (GaN) a me Silicon Carbide epitaxial CVD reactor nā ʻāpana me nā mea lawe wafer, nā kīʻaha ukali, nā poʻo ʻauʻau, nā kaupaku, a me nā mea kōkua.

• Silicon carbide, gallium nitride a me ka alumini nitride (AlN) mau mea ulu kristal me nā crucibles, nā mea paʻa hua, nā apo alakaʻi a me nā kānana.

• Nā ʻāpana ʻoihana e like me nā mea hoʻomehana kū'ē, nā nozzles injection, nā apo masking a me nā jigs brazing

Nā hiʻohiʻona noi:

• Paʻa ka mahana ma luna o 2000 ° C, e ʻae ana i ka hana ma nā wela wela

• Kū'ē i ka hydrogen (Hz), ammonia (NH3), monosilane (SiH4) a me ke silikoni (Si), e hāʻawi ana i ka palekana i nā wahi kemika paʻakikī.

• ʻO kona pale ʻana i ka haʻalulu wela e hiki ai i nā pōʻai hana wikiwiki

• He hoʻopili ikaika ka Graphite, e hōʻoiaʻiʻo ana i ka lōʻihi o ke ola lawelawe a ʻaʻohe delamination uhi.

• Maʻemaʻe Ultra-kiʻekiʻe e hoʻopau i nā mea haumia ʻole a i ʻole nā mea haumia

• ka uhi uhi kulike me ka hoomanawanui ana

Nā kikoʻī kikoʻī:

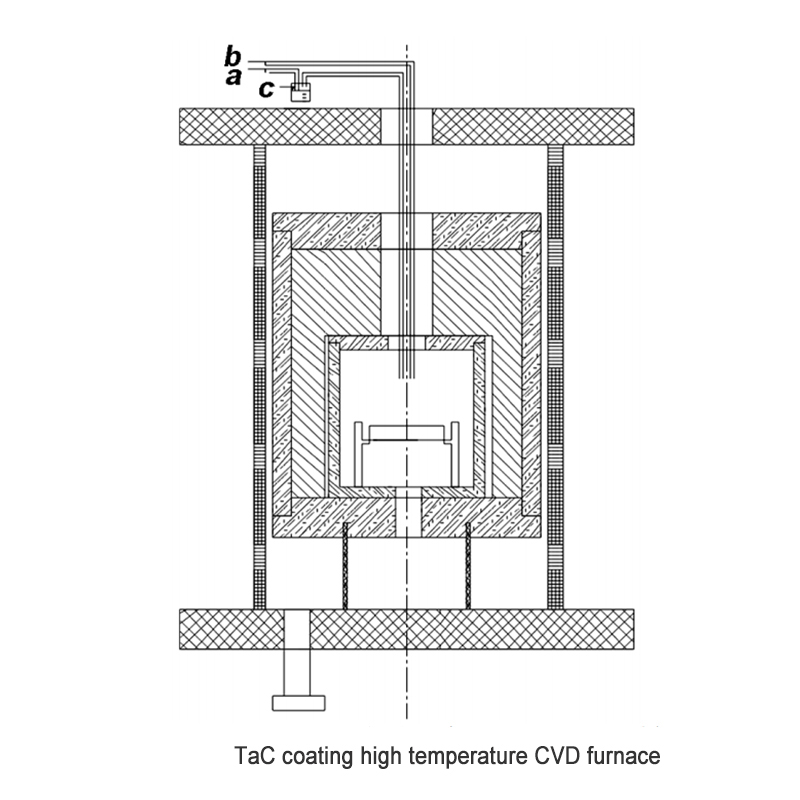

Ka hoʻomākaukau ʻana i nā uhi uhi tantalum carbide e CVD:

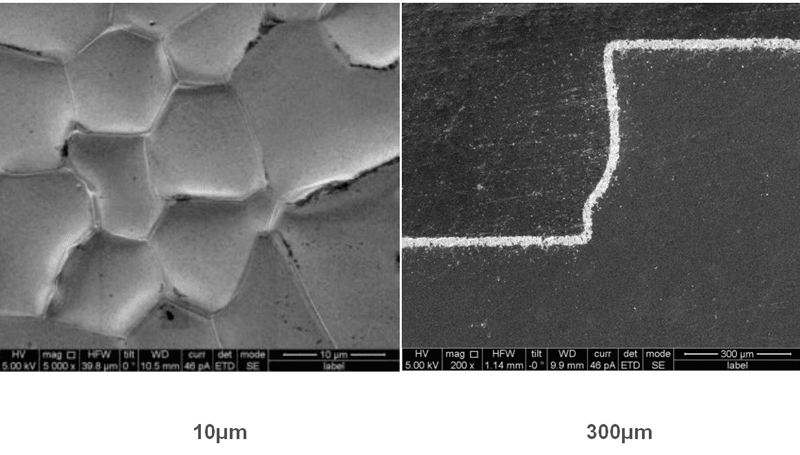

ʻO ka uhi TAC me ka crystallinity kiʻekiʻe a me ke kūlike maikaʻi loa:

CVD TAC COATING Nā ʻāpana ʻenehana_Semicera:

| Nā waiwai kino o ka uhi ʻana o TaC | |

| ʻO ka mānoanoa | 14.3 (g/cm³) |

| Hoʻopaʻa nui | 8 x 1015/cm |

| Emissivity kiko'ī | 0.3 |

| Koefficient hoʻonui wela | 6.3 10-6/K |

| 'Oolea(HK) | 2000 HK |

| Kū'ē nui | 4.5 ohm-cm |

| Kūʻē | 1x10-5ʻOhm*cm |

| Paʻa wela | <2500 ℃ |

| Ka neʻe ʻana | 237 knm2/Vs |

| Hoʻololi ka nui o ka graphite | -10~-20um |

| Mānoanoa uhi | ≥20um waiwai maʻamau (35um+10um) |

ʻO nā mea i luna he mau waiwai maʻamau.