I ke kaʻina hana semiconductor,kalai anaʻO ka ʻenehana kahi hana koʻikoʻi i hoʻohana ʻia no ka wehe pono ʻana i nā mea i makemake ʻole ʻia ma ka substrate e hana i nā ʻano kaapuni paʻakikī. E hōʻike ana kēia ʻatikala i ʻelua mau ʻenehana etching nui - capacitively coupled plasma etching (CCP) a me inductively coupled plasma etching (ICP), a e ʻimi i kā lākou mau noi i ke kālai ʻana i nā mea like ʻole.

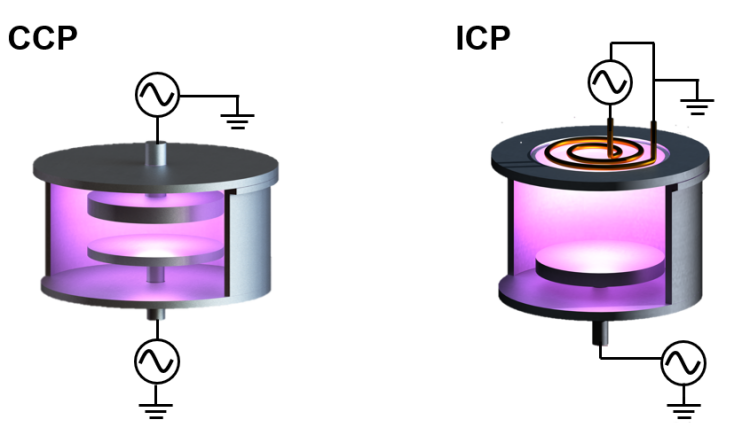

Hoʻopili ʻia ka plasma etching (CCP)

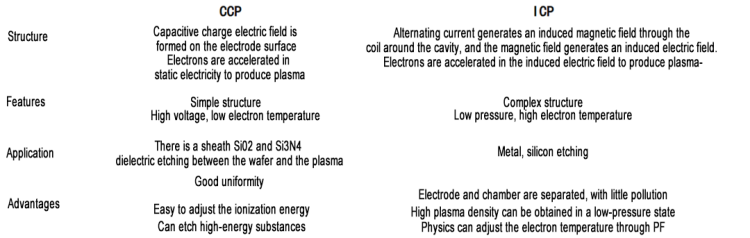

Loaʻa ka capacitively coupled plasma etching (CCP) ma o ka hoʻohana ʻana i ka volta RF i ʻelua electrodes plate parallel ma o kahi matcher a me kahi capacitor blocking DC. Hoʻokumu nā electrodes ʻelua a me ka plasma i kahi capacitor like. Ma kēia kaʻina hana, hana ka RF voltage i kahi capacitive sheath kokoke i ka electrode, a hoʻololi ka palena o ka sheath me ka oscillation wikiwiki o ka volta. I ka hiki ʻana o nā electrons i kēia puʻu e hoʻololi wikiwiki nei, e ʻike ʻia lākou a loaʻa ka ikehu, a laila e hoʻāla i ka dissociation a i ʻole ka ionization o nā molekele kinoea e hana i ka plasma. Hoʻohana pinepine ʻia ka etching CCP i nā mea me ka ikehu hoʻopaʻa kemika kiʻekiʻe, e like me ka dielectrics, akā ma muli o kona haʻahaʻa haʻahaʻa etching, kūpono ia no nā noi e koi ana i ka mana maikaʻi.

Hoʻopili ʻia ka plasma etching (ICP)

ʻO ka plasma i hoʻohui pū ʻiakalai anaHoʻokumu ʻia (ICP) ma ka loina e hele ana kahi au i loko o kahi wili e hoʻoulu ai i kahi māla magnetic induced. Ma lalo o ka hana a kēia māla magnetic, e hoʻokē ʻia nā electrons i loko o ke keʻena pane a hoʻomau i ka wikiwiki i loko o ke kahua uila i hoʻoulu ʻia, a laila e hui pū me nā molekele kinoea hopena, e hoʻokaʻawale ai i nā molekala a ionize a hana i ka plasma. Hiki i kēia ʻano hana ke hana i ka nui o ka ionization kiʻekiʻe a hiki ke hoʻoponopono kūʻokoʻa i ka density plasma a me ka ikehu bombardment.ICP kalaikūpono loa no nā mea etching me ka ikehu hoʻopaʻa kemika haʻahaʻa, e like me ke silikona a me ke metala. Eia kekahi, hāʻawi ka ʻenehana ICP i ka ʻoi aku ka maikaʻi a me ka helu etching.

1. Ke kalai metala

Hoʻohana nui ʻia ka etching metala no ka hana ʻana o nā interconnects a me nā wili metala multi-layer. ʻO kāna mau koi e like me: kiʻekiʻe etching rate, kiʻekiʻe ke koho (ʻoi aku ma mua o 4: 1 no ka papa mask a ʻoi aku ma mua o 20: 1 no ka interlayer dielectric), kiʻekiʻe etching uniformity, maikaʻi koʻikoʻi mana mana, ʻaʻohe pōʻino plasma, liʻiliʻi ke koena contaminants, a ʻaʻohe ʻino i ka metala. Hoʻohana pinepine ʻia ke kalai metala i nā mea hana etching plasma inductively.

•Aluminum etching: ʻO ka alumini ka mea uea koʻikoʻi ma waena a me hope o ka hana ʻana i ka chip, me nā pono o ka haʻahaʻa haʻahaʻa, maʻalahi ka waiho ʻana a me ka etching. Hoʻohana maʻamau ka kalai alumini i ka plasma i hana ʻia e ke kinoea chloride (e like me Cl2). Hoʻopili ka alumini me ka chlorine e hana i ka alumini chloride (AlCl3). Eia hou, hiki ke hoʻohuiʻia nā halides'ē aʻe e like me SiCl4, BCl3, BBr3, CCl4, CHF3, a me nā mea'ē aʻe e wehe i ka papa oxide ma kaʻili alumini e hōʻoia i ka etching maʻamau.

• Etching Tungsten: I loko o ka multi-layer metala interconnection hale, tungsten ka nui metala i hoʻohana 'ia no ka waena waena interconnection o ka chip. Hiki ke hoʻohana ʻia nā kinoea ma muli o ka fluorine a i ʻole ka chlorine no ke kālai ʻana i ka tungsten metala, akā ʻoi aku ka maikaʻi o ke koho ʻana o nā kinoea fluorine no ka silicon oxide, ʻoiai ʻoi aku ka maikaʻi o ke koho ʻana o nā kinoea chlorine (e like me CCl4). Hoʻohui pinepine ʻia ʻo Nitrogen i ke kinoea hopena no ka loaʻa ʻana o kahi koho kiʻekiʻe etching glue, a hoʻohui ʻia ka oxygen e hōʻemi i ka waiho ʻana o ke kalapona. Hiki i ka etching tungsten me ka chlorine-based gas ke hoʻokō i ka etching anisotropic a me ke koho kiʻekiʻe. ʻO nā kinoea i hoʻohana ʻia i ka etching maloʻo o ka tungsten ka nui o SF6, Ar a me O2, ma waena o ka SF6 hiki ke decomposed i loko o ka plasma e hāʻawi i nā atom fluorine a me ka tungsten no ka hopena kemika e hana i ka fluoride.

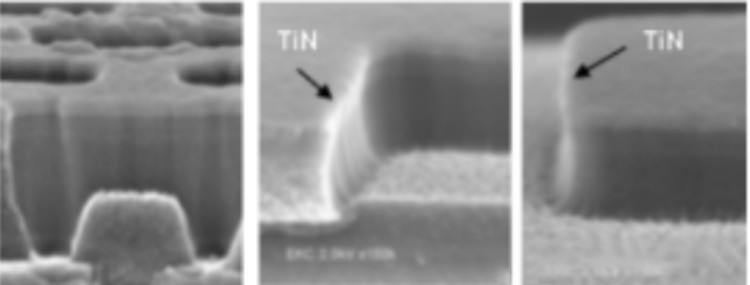

• Ke kalai ʻana i ka nitride Titanium: ʻO Titanium nitride, ma ke ʻano he mea pale paʻakikī, hoʻololi i ka nitride silicon a i ʻole mask oxide ma ke kaʻina hana pālua damascene. Hoʻohana nui ʻia ʻo Titanium nitride etching i ka wehe ʻana i ka mask paʻakikī, a ʻo ka huahana hopena koʻikoʻi ʻo TiCl4. ʻAʻole kiʻekiʻe ka koho ma waena o ka mask kuʻuna a me ka papa dielectric haʻahaʻa, kahi e alakaʻi ai i ke ʻano o ke ʻano o ka arc ma luna o ka papa haʻahaʻa-k dielectric a me ka hoʻonui ʻana i ka laula o ke awāwa ma hope o ka etching. ʻOi aku ka liʻiliʻi o ka mamao ma waena o nā laina metala i waiho ʻia, hiki ke hoʻopaʻa i ka leakage a i ʻole ka haki ʻana.

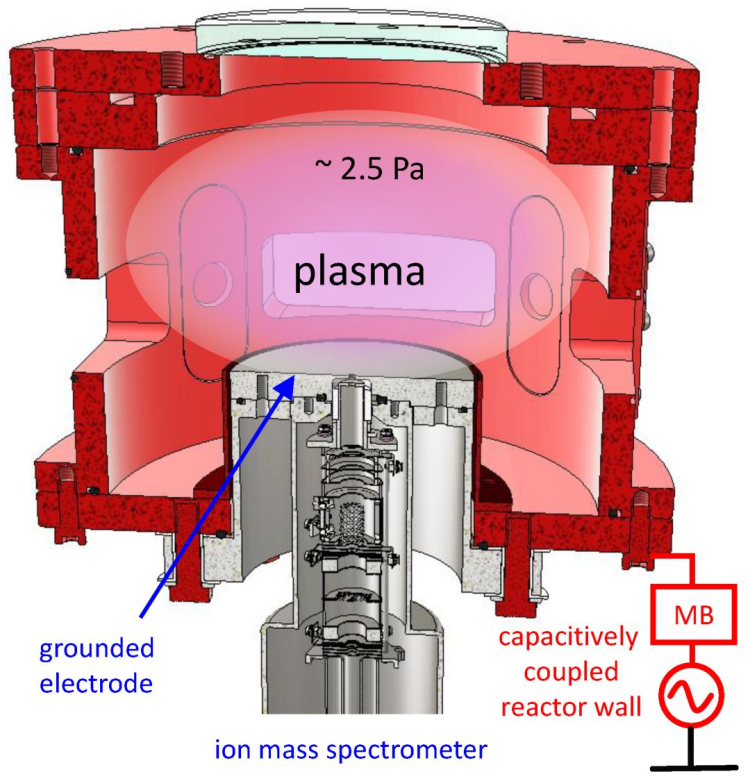

2. ukiuki insulator

ʻO ka mea o ka insulator etching ka maʻamau o nā mea dielectric e like me ka silicon dioxide a i ʻole silicon nitride, i hoʻohana nui ʻia e hana i nā lua hoʻopili a me nā lua kahawai e hoʻopili i nā papa kaapuni like ʻole. Hoʻohana maʻamau ka etching dielectric i kahi etch e pili ana i ke kumu o ka capacitively coupled plasma etching.

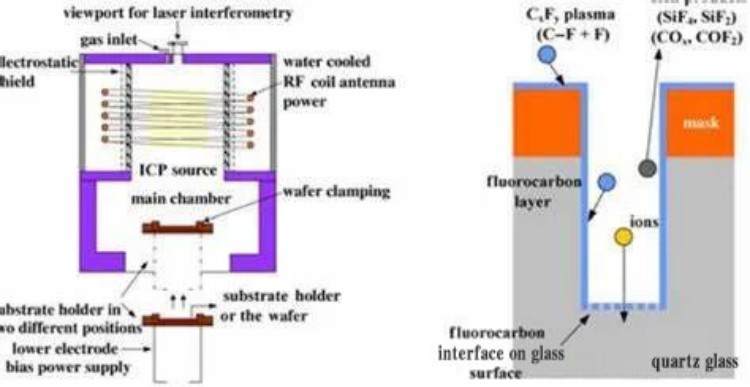

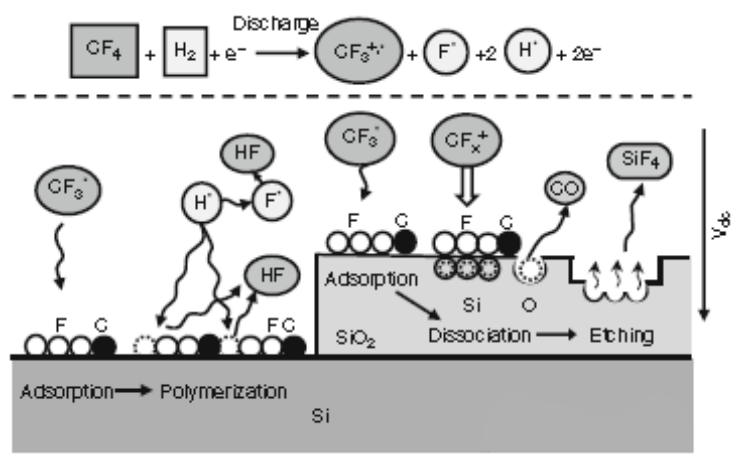

• Ke kalai plasma o ke kiʻiʻoniʻoni silicon dioxide: Hoʻohana mau ʻia ke kiʻi ʻoniʻoni silicon dioxide me ka hoʻohana ʻana i nā kinoea etching i loko o ka fluorine, e like me CF4, CHF3, C2F6, SF6 a me C3F8. Hiki i ke kalapona i loko o ke kinoea etching ke hana me ka oxygen i loko o ka papa oxide e hana i nā huahana CO a me CO2, a laila e hoʻoneʻe i ka oxygen i loko o ka papa oxide. ʻO CF4 ke kinoea etching maʻamau. Ke hoʻokuʻi ʻia ka CF4 me nā electrons ikaika nui, hana ʻia nā ion, radical, atoms a me nā radical manuahi. Hiki i nā radical free Fluorine ke hana kemika me SiO2 a me Si no ka hana ʻana i ka silicon tetrafluoride (SiF4).

• Ke kālai ʻia ʻana o ke kiʻiʻoniʻoni silicon nitride: Hiki ke kiʻi ʻia ke kiʻi ʻoniʻoni silicon nitride me ka hoʻohana ʻana i ka etching plasma me CF4 a i ʻole CF4 i hui pū ʻia (me O2, SF6 a me NF3). No ka kiʻiʻoniʻoni Si3N4, i ka wā e hoʻohana ʻia ai ka plasma CF4-O2 a i ʻole ke kinoea plasma i loaʻa nā F atoms no ka etching, hiki ke kiʻekiʻe ke kiʻekiʻe o ka silicon nitride i 1200Å/min, a hiki ke kiʻekiʻe ke koho etching e like me 20:1. ʻO ka huahana nui he volatile silicon tetrafluoride (SiF4) i maʻalahi ke lawe ʻia.

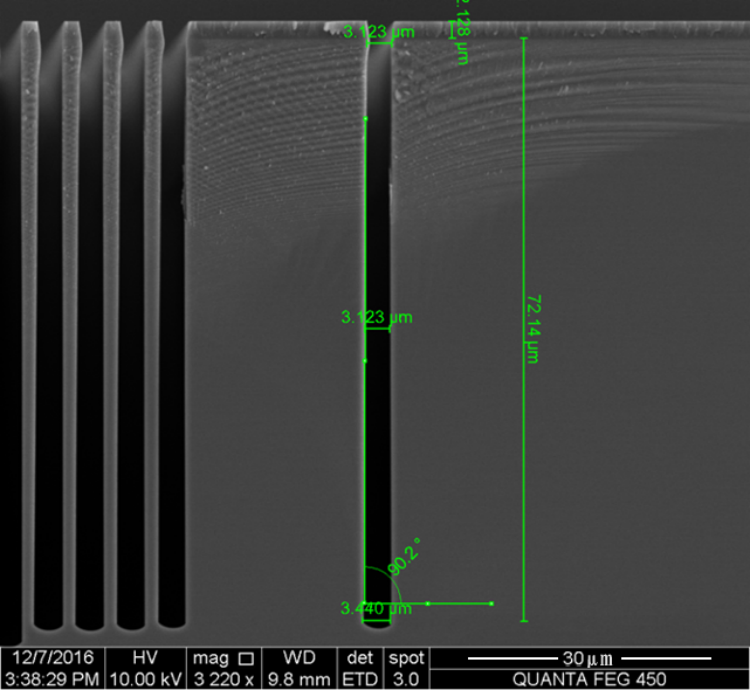

3. Hoʻokahi kalakala silika etching

Hoʻohana nui ʻia ka etching crystal silicone e hana i kahi kaʻawale pāpaʻu (STI). Hoʻokomo pinepine ʻia kēia kaʻina hana i kahi kaʻina holomua a me kahi kaʻina etching nui. Hoʻohana ke kaʻina hana i ka SiF4 a me ke kinoea NF no ka wehe ʻana i ka papa oxide ma ka ʻili o ka silika aniani hoʻokahi ma o ka pahū ʻana o ka ion ikaika a me ka hana kemika o nā mea fluorine; Hoʻohana ka etching nui i ka hydrogen bromide (HBr) ma ke ʻano he etchant nui. ʻO nā radical bromine i hoʻoheheʻe ʻia e HBr i loko o ke kaiapuni plasma e hoʻopili me ke silika e hana i ka tetrabromide silicon volatile (SiBr4), a laila e hoʻoneʻe i ke kilika. Hoʻohana maʻamau ka ʻili kilika aniani hoʻokahi i ka mīkini etching plasma inductively.

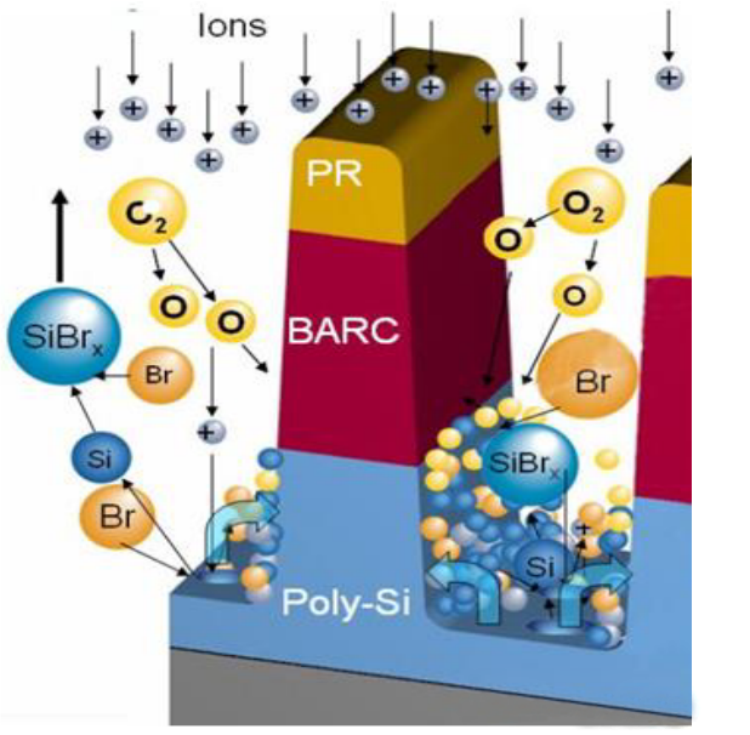

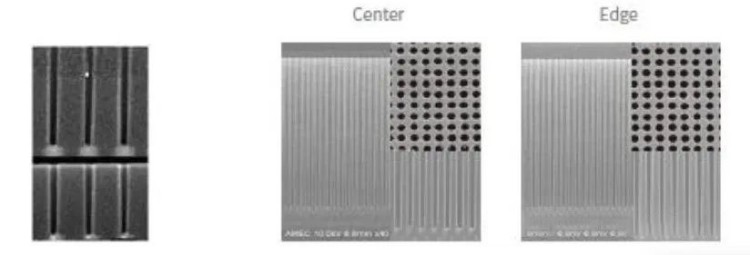

4. Polysilicon Etching

ʻO ka polysilicon etching kekahi o nā kaʻina hana nui e hoʻoholo ai i ka nui o ka puka o nā transistors, a pili pono ka nui o ka puka i ka hana o nā kaapuni hoʻohui. Pono ka etching polysilicon i kahi lakio koho maikaʻi. Hoʻohana mau ʻia nā kinoea halogen e like me ka chlorine (Cl2) no ka hoʻokō ʻana i ka etching anisotropic, a loaʻa ka lakio koho maikaʻi (a hiki i 10:1). Hiki i nā kinoea ma muli o ka bromine e like me ka hydrogen bromide (HBr) ke kiʻi i ka lakio koho kiʻekiʻe (a hiki i 100:1). Hiki i ka hui ʻana o HBr me ka chlorine a me ka oxygen ke hoʻonui i ka helu etching. Hoʻokomo ʻia nā huahana hopena o ke kinoea halogen a me ke silika ma nā ʻaoʻao ʻaoʻao e pāʻani i kahi hana pale. Hoʻohana maʻamau ʻo Polysilicon etching i ka mīkini etching plasma inductively.

Inā he capacitively coupled plasma etching a inductively coupled plasma etching, kēlā me kēia me kona pono pono'ī a me nā ʻano loea. ʻO ke koho ʻana i kahi ʻenehana etching kūpono ʻaʻole hiki ke hoʻomaikaʻi wale i ka hana hana, akā e hōʻoia pū i ka hua o ka huahana hope.

Ka manawa hoʻouna: Nov-12-2024